ลงชื่อเข้าใช้

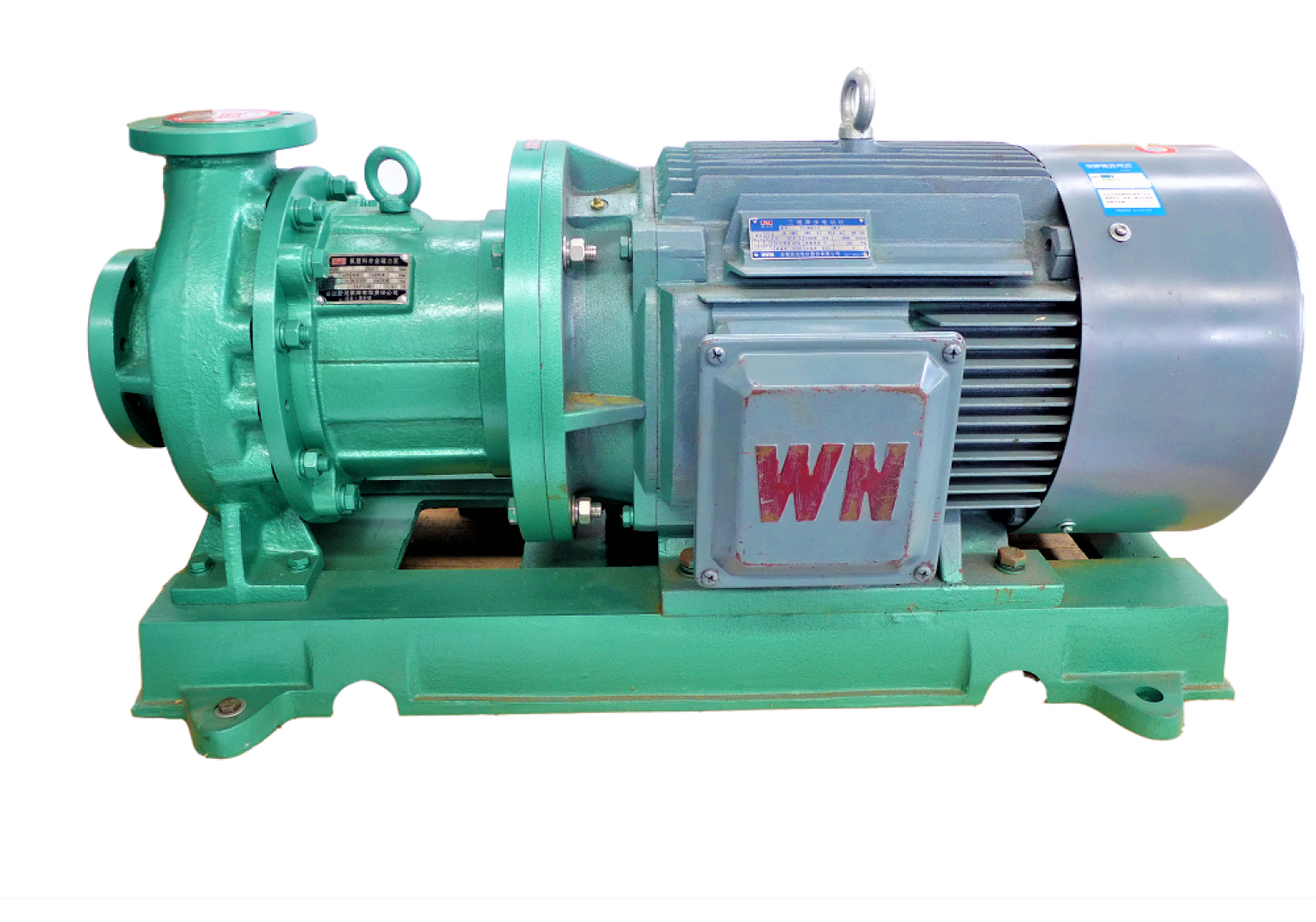

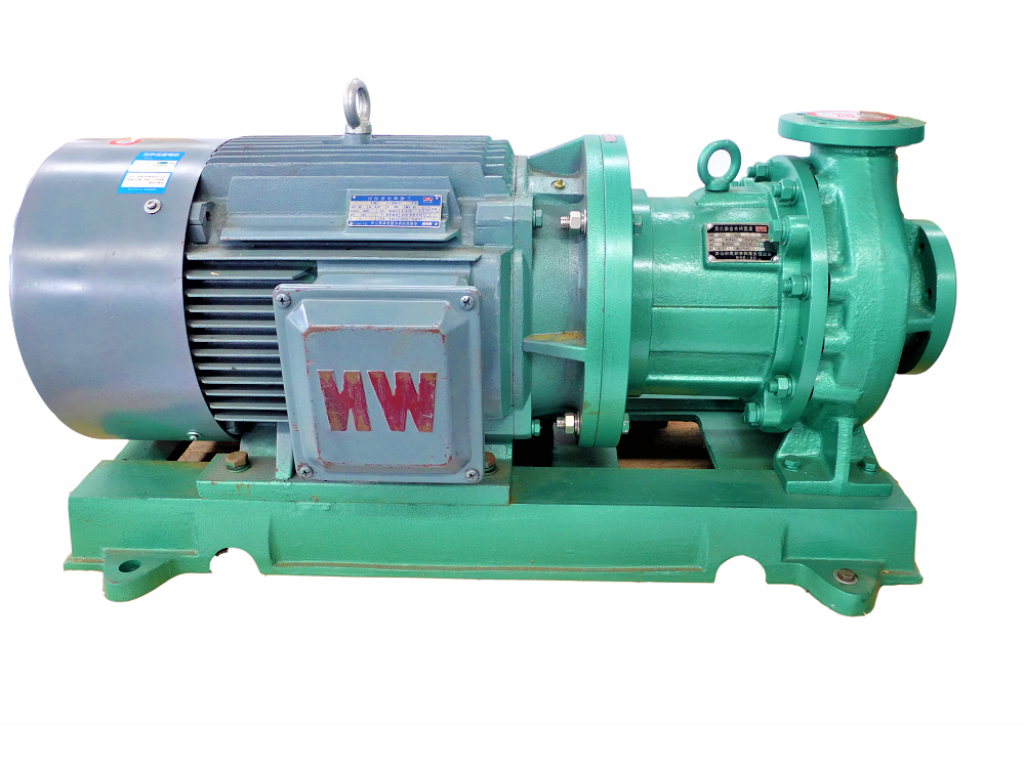

CQB-FB Magnetic Centrifugal Pump

รุ่นและพารามิเตอร์

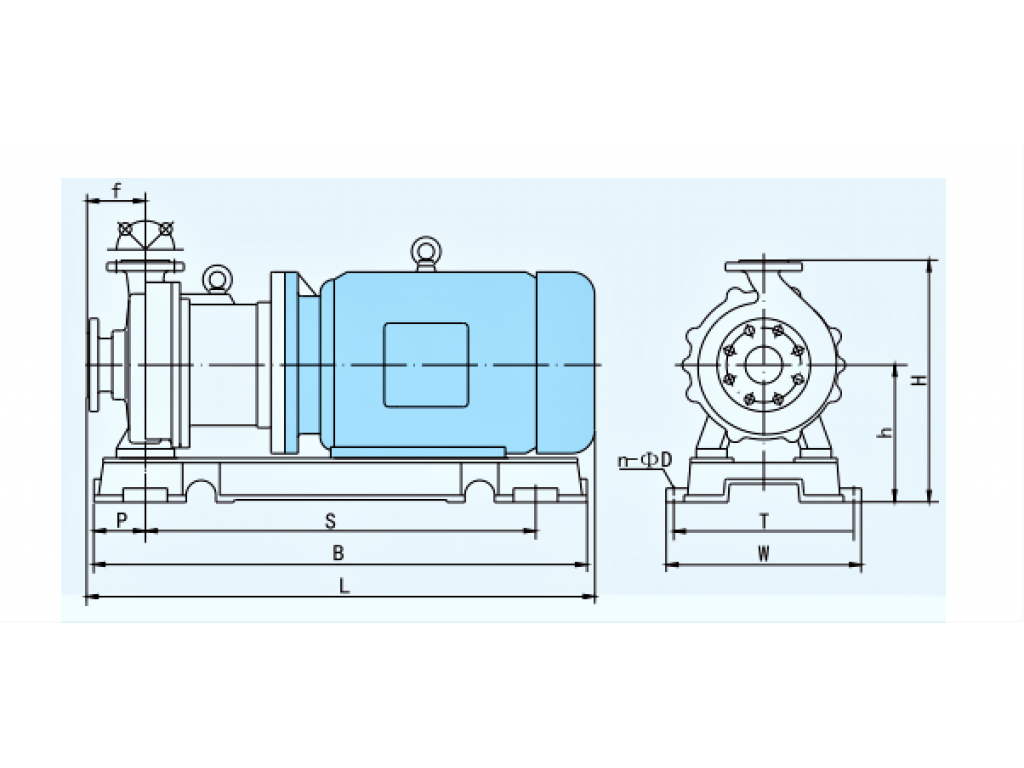

รุ่น : CQB80-50-250FB

การไหล : 35 ลบ.ม./ชม. , 50 ลบ.ม./ชม. , 60 ลบ.ม./ชม.

หัวปั๊ม : 82 ม. , 80 ม. , 75 ม.

ประสิทธิภาพ % : 45 , 51 , 53

NPSHa : 5 ม.

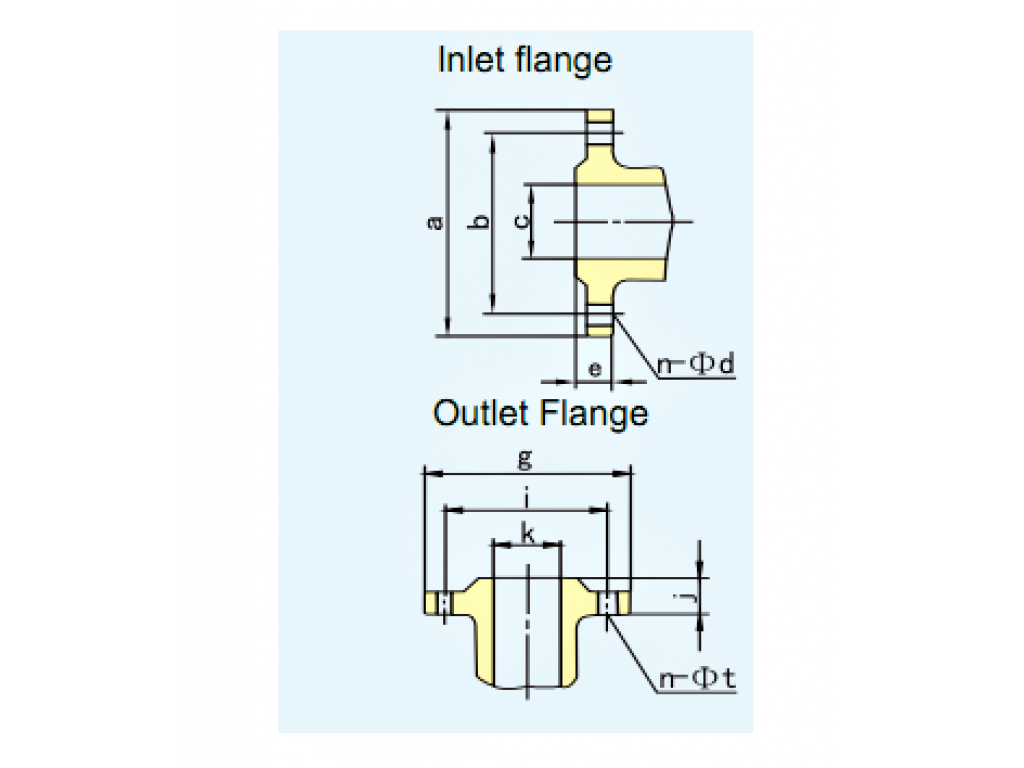

ทางเข้า*ทางออก : 80*50 มม.

ความเร็ว : 2900 รอบต่อนาที

กำลังไฟฟ้า : 30 กิโลวัตต์

น้ำหนักปั๊มและมอเตอร์ : 390 กก.

Model and Parameter

Model : CQB80-50-250FB

Flow : 35 m3/h , 50 m3/h , 60 m3/h

Pump head : 82 m , 80 m , 75 m

Efficiency % : 45 , 51 , 53

NPSHa : 5 m

Inlet*Outlet : 80*50 mm

Speed : 2900 rpm

Power : 30 kw

Pump and motor weight : 390 kg

Application

- Application : Chemical and petrochemical industries. Acids &lyes. Metal Pickling. Rare-earth separation. Agricultural chemicals. Nonferrous

smelting process. Dyes. Pharmaceutical. Pulp and Paper. Electroplating industry. Radio Industry

- Pumping Liquid : Acid and caustic liquid. Oxidizer corrosive liquids. Difficult-to-seal liquids. Sulfuric acid. Hydroelectric acid. nitric acid.

Acid and lye. nitromuriatic acid

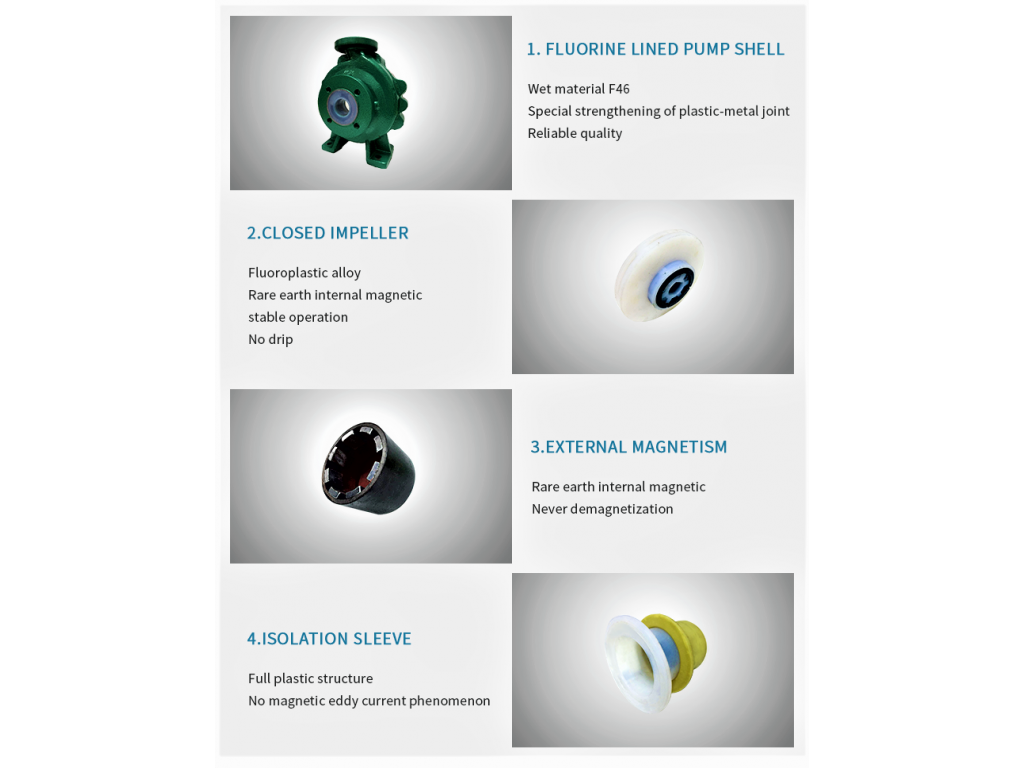

Design Feature

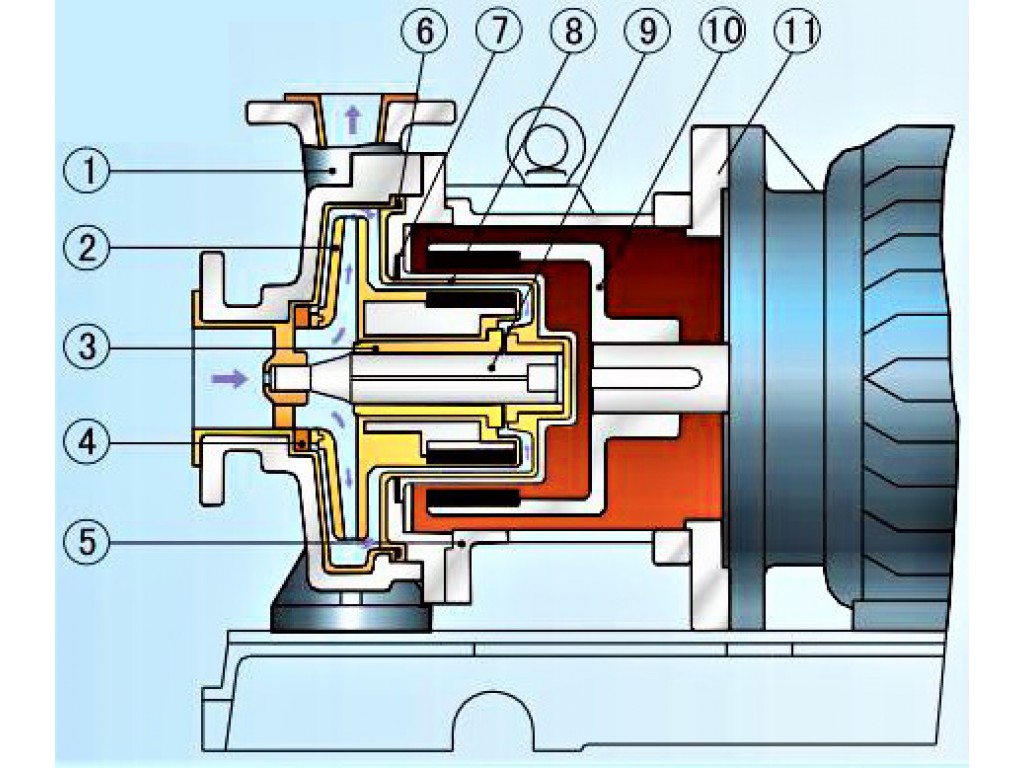

- Leak-proof design : Seal-less Teflon lined magnetic drive pump, driven by magnetic coupling indirectly, motor shaft and pump chamber is

completely sealed, avoid pump leakage problem and use site pollution.

- Anti-Corrosive

1. Wetted part material is PTFE fused with FEP, can transfer low and high concentration acid, alkali, strong oxidizer etc corrosive liquid. Robust

pump casing.

2. The part contacting with liquid material is fluoroplastic, pump casing material is cast iron, and pump casing can bear part of piping and mechanical

impact.The structure is tightly, safety, and energy-saving.

3. Cost-intensive wearing parts are canceled by the seal-less method of construction, therefore, reduced maintenance costs and long service life.

With ductile cast iron casing absorbs all the hydraulic and pipe work-forces. According to DIN/ISO5199/Europump 1979 standard. Comparing to

plastic pumps, no expansion joints are required.Flangewith service-minded through holes to DIN;ANSI,BS;JIS. For flushing system and monitoring

device as required, the draining nozzle will be offered.

- Spacer sleeve made of Carbon-fiber-reinforced plastic [CFRP] : The metal-free system does not induce any eddy currents and thus avoids unnecessary

heat generation. Efficiency and operational reliability benefit from this. Even low flow rates or media near their boiling point can therefore be conveyed

without the introduction of heat.

- Close Impeller : Closed impeller with flow-optimized vane channels: for high efficiency and low NPSH values. The metal core is protected by a thick-

walled seamless plastic lining, the large metal core and increase the mechanical strength considerably even at elevated temperature and high flow rates .

Secured screw connection to the shaft to against loosening if the pump is started up in the wrong direction of rotation or in the case of back-flowing media

|

|

ความคิดเห็นเกี่ยวกับตัวสินค้า

ชื่อ:

เขียนความคิดเห็นของคุณ:

รูปภาพ (Upload Multiple images) :

| Review Images | Delete |

วีดีโอ (Enter Youtube video link) :

ให้คะแนน: น้อย

การชำระเงิน |

กรุณาโอนเงินเข้าบัญชี ธนาคาร กสิกรไทย สาขา คลอง 6 ธัญบุรี ชื่อบัญชี บจก.เจช้อปดีแอล เลขที่บัญชี 119-347-595-3 โปรติดต่อฝ่ายขาย 061-5597151 ก่อนการโอน |

|

|

หมายเลขอ้างอิง: 4354

Capacity: 200 GPM – 2000 GPM

Pressures: 40 – 355 psi

Maximum Working Pressures: 290 to 395 PSI

Speed: 1480,1760, 2900,2980, 3000 RPM

Dynamically Balanced Impeller extends bearing life and ensures smoother operation.

Designed and built as per UL 448 AND NFPA20 for maximum reliability.

Constructed in variety of metallurgies.

Available in 50 Hz and 60 Hz.

Drivers with gear boxes at electric and diesel speeds.

Designed for easy maintenance without interfering with piping.

Open line shaft, water lubricated construction for ease of maintenance.

Self-Venting Design eliminates vapor lock and the need for automatic air release valve

ประตูน้ำเหล็กหล่อ : ลิ้นยกแบบรองลิ้นโลหะ สำหรับงานประปา CASR IRON GATE VALVE – METAL SEATED FOR WATER SERVICES MODEL (DN-CI-MS) TIS 256 PN 6, 10, 16 TIS 432 PN 6, 10, 16 DIN 3352 PN 10, 16 BS 5150 PN 6, 10, 16 BS EN 1171 PN 6, 10, 16 Size DN80-1200 mm. ประตูน้ำ (Gate Valve) เหล็กหล่อใต้ดิน ชนิดลิ้นยกแบบรองลิ้นโลหะ มอก.256 ประตูน้ำ (Gate Valve) เหล็กหล่อใต้ดิน ชนิดลิ้นยกแบบรองลิ้นโลหะ สำหรับงานประปา มอก.256 วาล์วได้ผลิตและทดสอบตามมาตรฐาน BS 5150 PN10/16/25, BS EN 1171:2002, BS EN 1074-2, TIS 432 PN 6 / 10 / 16 และสอดคล้องกับข้อกำหนดของ MSS-SP-70 class 125 / 250 ใช้งานได้กับทั้งน้ำ, อากาศและไอน้ำ ตุณลักษณะ - ตัวเรือนเป็นเหล็กหล่อ - ปลายประตูน้ำ สามารถเป็นหน้าจาน, เกลียวและปลายเรียบ - หน้าจานสามารถเจาะให้เข้ากับ ANSI B16.1, ANSI B16.5, BS4504, BS10, BS EN 1092-2, BS 4772, AS2129, DIN, JIS และอื่น ๆ - เลือกตัวขับได้หลากหลาย ตามที่ต้องการเช่น พวงมาลัย, แป้นประแจขันหรือ cap, พวงมาลัยโซ่, เฟืองตรง, เฟืองดอกจอก, นิวเมติก, ไฮดรอลิก และไฟฟ้า

Fire Pump Controller UL FM standard for Jockey Pump Type You have decided to reduce the risk of fire damage to your facility by installing a UL, ULC listed fire pump system. Your next decision is which system to purchase. You want a fire pump that is proven in installations worldwide. Manufactured by an professional with vast experience in the fire protection field. You want complete service to field start-up. You want a Engine Controller Fire Protection UL FM Providing Pumping Solutions TONGKE Can Fulfill Your Requirements: Complete in-house fabrication capabilities Mechanical-run test capabilities with customer furnished equipment for all NFPA standards Horizontal models for capacities to 2,500 gpm Vertical models for capacities to 5,000 gpm In-line models for capacities to 1,500 gpm End suction models for capacities to 1,500 gpm Drives: electric motor or diesel engine Basic units and packaged systems.

กลุ่มผลิตภัณฑ์เดียวกันที่น่าซื้อ

-

Daily Chemicals Transfer Pump 3RP-650.00 บาท

-

Heat Jacket Gear Pump RCB-580.00 บาท

-

Hopper Screw Pump G20-10.00 บาท

-

Hopper Screw Pump G30-20.00 บาท

-

ปั๊มไดอะแฟรมแบบใช้ไฟฟ้า SKD-500.00 บาท

-

ปั๊มเคมี Magnetic drive pump MPH-5630.00 บาท

-

ปั๊มเกียร์สแตนเลส YCB3.3-1.60.00 บาท

-

ปั๊มหอยโข่ง 25FSB-250.00 บาท

-

ปั๊มเคมีความหนืดสูง LQB-18/0.360.00 บาท

-

ปั๊มหอยโข่ง RY 65-40-3150.00 บาท

-

ปั๊มหอยโข่ง 80FSB-500.00 บาท

-

Lobe Pump With Cone Reducer 3RP-800.00 บาท

-

ปั๊มแก๊ส API 610 DFAY0.00 บาท

-

Gear Pump Bitumen / Asphalt LCB1/0.60.00 บาท

-

ปั๊มเกียร์ภายในสำหรับเรซิน NYP1600.00 บาท

-

Asphalt Pump with jacket RCB2.2/0.60.00 บาท

-

ปั๊มเกียร์ Gear Pump KCB-56000.00 บาท

-

Centrifugal Chemical Pump 50FSB-300.00 บาท

-

ปั๊มหอยโข่ง RY 50-32-1600.00 บาท

-

ปั๊มเกียร์น้ำมัน KCB9600.00 บาท

-

ปั๊มหอยโข่ง Self-priming 50ZX18-200.00 บาท

-

Chemical Pump 80FYH-250.00 บาท

-

ปั๊มหอยโข่ง RY 80-50-3150.00 บาท

-

ปั๊มเกียร์ภายใน NYP3.60.00 บาท

-

ปั๊มเกียร์สแตนเลส YCB3.3-0.60.00 บาท

-

Gear Pump Bitumen / Asphalt LCB6/0.60.00 บาท

-

Bitumen Jacketed Asphalt Pump NYP7.00.00 บาท

-

ปั๊มเกียร์ stainless steel YCB30-0.60.00 บาท

-

KCB ปั๊มเกียร์ รุ่น KCB-550.00 บาท

-

Lobe Pump พร้อมเครื่องบรรจุ 3RP-500.00 บาท

-

Lobe Pump With Cone Reducer 3RP-250.00 บาท

-

High Temperature Gear Pump 2CG-180.00 บาท

-

Magnetic pump CQB80-50-200FD0.00 บาท

-

Pump Bitumen & Asphalt CBN-130.00 บาท

-

Self-priming Pump 100FZB-45L0.00 บาท

-

ปั๊มหอยโข่ง Plastic 80FSB-40L0.00 บาท

-

High Temperature Gear Pump 2CG-1500.00 บาท

-

Daily Chemicals Transfer Pump 3RP-800.00 บาท

-

ปั๊มเกียร์ stainless steel YCB60-0.60.00 บาท

-

ปั๊มท่อปิโตรเคมี Dfgy-P0.00 บาท

-

ปั๊มเคมี Fluorine Plastic IHF0.00 บาท

-

ปั๊มเกียร์สแตนเลส YCB0.6-0.60.00 บาท

-

KCB Gear Pump Model KCB-6330.00 บาท

-

Food Grade Rotary Lobe Pump 3RP-500.00 บาท

-

Slurry Pump UHB-ZK65/30-500.00 บาท

-

Slurry Pump UHB-ZK65/25-800.00 บาท

-

ปั๊มเกียร์สแตนเลส YCB1.6-1.60.00 บาท

-

ปั๊มหอยโข่งพลาสติก 40FSB-15L0.00 บาท

-

KCB Gear Pump Model KCB-483.30.00 บาท

-

Heat Jacket Gear Pump RCB-720.00 บาท

-

Pump Bitumen & Asphalt CBN-300.00 บาท

-

ปั๊มเกียร์ stainless steel YCB10-0.60.00 บาท

-

ปั๊มโรเตอร์ความหนืดสูง NCB8/0.50.00 บาท

-

Centrifugal Chemical Pump 80FSB-200.00 บาท

-

Magnetic Drive Pump SX-4410.00 บาท

-

Centrifugal Chemical Pump 80FSB-500.00 บาท

-

Self-priming Pump 40FZB-30L0.00 บาท

-

ปั๊มหอยโข่ง Plastic 100FSB-32L0.00 บาท

-

ปั๊มหอยโข่งแนวนอน DH0.00 บาท

-

Slurry Pump UHB-ZK65/30-300.00 บาท

-

ปั๊มเคมี Bitumen / Asphalt NYP16700.00 บาท

-

Self-priming Pump 100FZB-45L0.00 บาท

-

Chemical Pump FYH 50FYH-250.00 บาท

-

ปั๊มหอยโข่งแนวนอน DHP0.00 บาท

-

ปั๊มหอยโข่งหลายใบพัด D720-60x40.00 บาท

-

ปั๊มเคสแยกคุณภาพสูง XS400-6650.00 บาท

-

Flowing Parts Centrifugal Pumps IHH0.00 บาท

-

ปั๊มหอยโข่งเคมี IHF32-25-160A0.00 บาท

-

Slag Oil Pump ZYB45/0.40.00 บาท

-

Hopper Screw Pump G105-20.00 บาท

-

ปั๊มเคมีสแตนเลส CQ32-20-2000.00 บาท

-

ปั๊มเคมี Fluoroplastics Liner IHF0.00 บาท

-

High Temperature Gear Pump 2CG-720.00 บาท

-

ปั๊มเคมีสแตนเลส CQ40-25-2500.00 บาท

-

ปั๊มโรตารี่ For Asphalt LCT-38/0.60.00 บาท

-

SS Magnetic Pump CQ0.00 บาท

-

Internal Gear Pump NYP7.00.00 บาท

-

ปั๊มหอยโข่ง self-priming 100CYZ-A-750.00 บาท

-

Gear Pump Bitumen / Asphalt LCB2/0.60.00 บาท

-

ปั๊มเคมี Under-Water FY0.00 บาท

-

ปั๊มหอยโข่งสแตนเลส IH40-32-1600.00 บาท

-

ปั๊มน้ำใบพัด Propeller Pump0.00 บาท

-

High Temperature Gear Pump 2CG-7.50.00 บาท

-

High Temperature Gear Pump 2CG-960.00 บาท

-

KCB Gear Pump Model KCB-9600.00 บาท

-

Internal Gear Pump NYP1110.00 บาท

-

Slurry Pump UHB-ZK80/50-500.00 บาท

-

ปั๊มสูบน้ำเสีย / ปั๊มบำบัดน้ำเสีย0.00 บาท

-

Hopper Screw Pump G105-10.00 บาท

-

High Temperature Gear Pump 2CG-100.00 บาท

-

Slurry Pump UHB-ZK65/30-200.00 บาท

-

ตลับกรองไฟฟ้า PFG-3180.00 บาท

-

Lobe Pump With Cone Reducer 3RP-650.00 บาท

-

ปั๊มหอยโข่ง 50FSB-25(D)0.00 บาท

-

ปั๊มหอยโข่ง 40FSB-20(D)0.00 บาท

-

Gear Pump Bitumen / Asphalt LCB7/0.60.00 บาท

-

Roots oil pump ความหนืดสูง LC-50/0.60.00 บาท

-

ปั๊มหอยโข่ง RY 50-32-2500.00 บาท

-

ปั๊มหอยโข่ง RY 40-25-1600.00 บาท

-

ปั๊มไดอะแฟรม Diaphragm Pump SJM0.00 บาท

-

ปั๊มเกียร์ stainless steel YCB8-1.60.00 บาท

-

ปั๊มหอยโข่ง 40FSB-30(D)0.00 บาท

-

ปั๊มหอยโข่ง 50FSB-200.00 บาท

-

High Temperature Gear Pump 2CG-580.00 บาท

-

YQB pump YQB60-50.00 บาท

-

ปั๊มหอยโข่ง Plastic 80FSB-20L0.00 บาท

-

ปั๊มหอยโข่ง 65FSB-320.00 บาท

-

ปั๊มหอยโข่ง Self-priming 50ZX15-120.00 บาท

-

Magnetic pump CQB100-80-160FD0.00 บาท

-

Slag Oil Pump ZYB18/0.60.00 บาท

-

Internal gear pump for soap0.00 บาท

-

LPG Transfer Pump YQB35-50.00 บาท

-

High Temperature Gear Pump 2CG-60.00 บาท

-

ปั๊มเกียร์เคมีสแตนเลส 15SKCQB-100.00 บาท

-

Magnetic Pump CQB80-65-160FD0.00 บาท

-

KCB ปั๊มเกียร์ รุ่น KCB-1350.00 บาท

-

ปั๊มเคมีความหนืดสูง LQB-58/0.360.00 บาท

-

Slurry Pump UHB-ZK40/10-300.00 บาท

-

ปั๊มหอยโข่ง RY 65-40-200A0.00 บาท

-

ปั๊มไดอะแฟรมไฮดรอลิก SJ-M0.00 บาท

-

ปั๊มเคมี / ปั๊มหอยโข่ง IHH0.00 บาท

-

ปั๊มหอยโข่งสแตนเลส IH25-25-2000.00 บาท

-

YQB pump YQB50-50.00 บาท

-

Self-priming Pump 80FZB-70L0.00 บาท

-

Teflon lining magnetic pump CQB0.00 บาท

-

ปั๊มเครื่องสูบน้ำแนวตั้ง0.00 บาท

-

ปั๊มไดอะแฟรมแบบใช้ไฟฟ้า SKD-40A0.00 บาท

-

ปั๊มหอยโข่ง 80FSB-550.00 บาท

-

Lobe Pump พร้อมเครื่องบรรจุ 3RP-400.00 บาท

-

ปั๊มเกียร์ stainless steel YCB25-0.60.00 บาท

-

ปั๊มโรตารี่ For Asphalt LCT-80/0.60.00 บาท

-

Daily Chemicals Transfer Pump 3RP-250.00 บาท

-

Heat Jacket Gear Pump RCB-290.00 บาท

-

Self-priming Pump 60FZB-30L0.00 บาท

-

ปั๊มเคมีแนวตั้ง PP Vertical0.00 บาท

-

Slag Oil Pump ZYB4/0.60.00 บาท

-

Slurry Pump UHB-ZK50/20-300.00 บาท

-

ปั๊มเกียร์ Gear Pump KCB-96000.00 บาท

-

ปั๊มโรเตอร์ความหนืดสูง NCB12/0.70.00 บาท

-

Slurry Pump UHB-ZK200/400-320.00 บาท

-

Self-priming Pump 50FZB-70L0.00 บาท

-

ปั๊มลูกสูบแรงดันสูง SHP350.00 บาท

-

Food Grade Rotary Lobe Pump 3RP-1250.00 บาท

-

ปั๊มน้ำมัน Oil Pump DFAY0.00 บาท

-

Hopper Screw Pump G30-10.00 บาท

-

ปั๊มหอยโข่งสแตนเลส IH40-32-2000.00 บาท

-

YQB pump YQB80-50.00 บาท

-

ปั๊มเคมีแนวนอน DFCZ0.00 บาท

-

Lobe Pump พร้อมเครื่องบรรจุ 3RP-100A0.00 บาท

-

Magnetic Centrifugal Pump CQB-FB0.00 บาท

-

ปั๊มเคมี Hot Water Circulation HPK0.00 บาท

-

Triple Screw Asphalt Pump 3QGB0.00 บาท

-

Plastic Centrifugal Pump 40FSB-15D0.00 บาท

-

LPG Transfer Pump YQB50-50.00 บาท

-

ปั๊มเคมี magnetic drive SX-4530.00 บาท

-

High Temperature Gear Pump 2CG-30.00 บาท

-

ปั๊มสารเคมี / ปั๊มปิโตรเคมี DFGY0.00 บาท

-

Pump Bitumen & Asphalt CBN-450.00 บาท

-

ปั๊มเคมี Chemical Pump IHF0.00 บาท

-

Daily Chemicals Transfer Pump 3RP-400.00 บาท

-

Plastics Self-Priming Pump 40FZB-200.00 บาท

-

Hopper Screw Pump G135-10.00 บาท

-

ปั๊มเคมีพลาสติกฟลูออรีน CQB20-15-75F0.00 บาท

-

Intubation stylet magnetic pump CQB0.00 บาท

-

Centrifugal Chemical Pump 25FSB-250.00 บาท

-

Internal Gear Pump NYP3200.00 บาท

-

ปั๊มเคมี Horizontal DFCZ0.00 บาท

-

YQB pump YQB35-50.00 บาท

-

Magnetic Pump ZCQ40-32-1600.00 บาท

-

ปั๊มเคมีสแตนเลส CQ40-25-1250.00 บาท

-

ปั๊มหอยโข่ง RY 100-65-250B0.00 บาท

-

Self-priming Pump 80ZMD-32F0.00 บาท

-

ปั๊มหอยโข่ง Self-priming 40ZX6.3-200.00 บาท

-

Food Grade Rotary Lobe Pump 3RP-800.00 บาท

-

ปั๊มหอยโข่ง Plastic 80FSB-50L0.00 บาท

-

KCB ปั๊มเกียร์ รุ่น KCB-2000.00 บาท

-

ปั๊มเคมี Chemical Pump DFCZ0.00 บาท

-

Slurry Pump UHB-ZK100/100-800.00 บาท

-

Electric Diaphragm Pump SKD-800.00 บาท

-

Centrifugal Chemical Pump 40FSB-300.00 บาท

-

Electric Diaphragm Pump SKD-1250.00 บาท

-

ปั๊มหอยโข่ง RY 125-100-2000.00 บาท

-

Lobe Pump With Cone Reducer 3RP-1250.00 บาท

-

Oil Chemical Centrifugal Pump ZA0.00 บาท

-

Self-priming Pump 50FZB-45L0.00 บาท

-

Slag Oil Pump ZYB13/1.00.00 บาท

-

Self-priming Pump 40ZMD-32F0.00 บาท

-

ปั๊มไดอะแฟรมนิวเมติก Aluminum Alloy0.00 บาท

-

Bitumen Jacketed Asphalt Pump NYP2.30.00 บาท

-

Self-priming Pump 25FZB-20L0.00 บาท

-

Daily Chemicals Transfer Pump 3RP-250.00 บาท

-

ปั๊มหอยโข่งพลาสติก 50FSB-30L0.00 บาท

-

ปั๊มหอยโข่ง RY 125-100-250A0.00 บาท

-

ปั๊มเคมี Mixed Flow SPP0.00 บาท

-

Self-priming Pump 65FZB-45L0.00 บาท

-

High Temperature Gear Pump 2CG-1120.00 บาท

-

ปั๊มหอยโข่ง self-priming 250CYZ-A-500.00 บาท

-

YQB pump YQB10-50.00 บาท

-

ปั๊มโรตารี่ For Asphalt LCT-18/0.60.00 บาท

-

ปั๊มไดอะแฟรมแบบใช้ไฟฟ้า SKD-25A0.00 บาท

-

Heat Jacket Gear Pump RCB-650.00 บาท

-

High Temperature Gear Pump 2CG-150.00 บาท

-

ปั๊มหอยโข่งแนวนอน DFW0.00 บาท

-

ปั๊มหอยโข่งแยกก้นหอย 800MS800.00 บาท

-

Food Grade Rotary Lobe Pump 3RP-650.00 บาท

-

ปั๊มหอยโข่งเคมี IHF40-32-125A0.00 บาท

-

ปั๊มหอยโข่ง 80FSB-25(D)0.00 บาท

-

Centrifugal Chemical Pump 80FSB-500.00 บาท

-

ปั๊มไดอะแฟรมแบบใช้ไฟฟ้า SKD-400.00 บาท

-

Chemical Submerged Pump HY0.00 บาท

-

ปั๊มหอยโข่ง RY 80-50-200A0.00 บาท

-

Self-priming Pump 50ZMD-32F0.00 บาท

-

ปั๊มหอยโข่ง 65FSB-32(D)0.00 บาท

-

ปั๊มเคมี Petrochemical Pump DFGY-P0.00 บาท

-

Centrifugal Chemical Pump 50FSB-250.00 บาท

-

Self-priming Pump 65ZMD-32F0.00 บาท

-

Hopper Screw Pump G85-20.00 บาท

-

ปั๊มหอยโข่ง 50FSB-20(D)0.00 บาท

-

ปั๊มหอยโข่ง hot oil pump RY20-20-1000.00 บาท

-

Centrifugal Chemical Pump 40FSB-200.00 บาท

-

Centrifugal Chemical Pump 80FSB-550.00 บาท

-

Stainless steel magnetic pump CQ0.00 บาท

-

High-pressure Pumps SHP0.00 บาท

-

Centrifugal Chemical Pump 50FSB-250.00 บาท

-

API 610 Between Bearing Pump(HBR)0.00 บาท

-

Slurry Pump UHB-ZK100/60-350.00 บาท

-

ปั๊มหอยโข่ง 80FSB-400.00 บาท

-

ปั๊มน้ำมันร้อนขับเคลื่อนด้วยแม่เหล็ก0.00 บาท

-

ปั๊มหอยโข่ง RY 125-100-200A0.00 บาท

-

KCB Gear Pump Model KCB-18000.00 บาท

-

Centrifugal Chemical Pump 100FSB-320.00 บาท

-

ปั๊มมัลติสเตจ D6-25-70.00 บาท

-

Chemical Pump 25FYH-250.00 บาท

-

Plastic Centrifugal Pump 40FSB-30D0.00 บาท

-

Internal Gear Pump NYP1600.00 บาท

-

Self-priming Pump 50FZB-30L0.00 บาท

-

Three screw booster pump SPF0.00 บาท

-

ปั๊มหอยโข่งพลาสติก 40FSB-20L0.00 บาท

-

ปั๊มหอยโข่งพลาสติก 50FSB-20L0.00 บาท

-

ปั๊มไดอะแฟรมแบบใช้ไฟฟ้า SKD-150.00 บาท

-

Lobe Pump 3RP-1250.00 บาท

-

Corrosiveless Under-Water Pump FY0.00 บาท

-

ปั๊มเคมี Chemical Pump SHY0.00 บาท

-

ปั๊มหอยโข่งพลาสติก 25FSB-25L0.00 บาท

-

ปั๊มเกียร์ภายใน Sumitomo QT520.00 บาท

-

ตัวกรองการชุบด้วยไฟฟ้า PP0.00 บาท

-

ปั๊มหอยโข่ง Plastic 80FSB-30L0.00 บาท

-

Self-priming Pump 40FZB-200.00 บาท

-

Centrifugal Chemical Pump 80FSB-550.00 บาท

-

ปั๊มเกียร์น้ำมัน KCB83.30.00 บาท

-

ปั๊มเกียร์ magnetic drive KCB-M0.00 บาท

-

ปั๊มเคมี / ปั๊มหอยโข่ง IHK0.00 บาท

-

YQB pump YQB25-50.00 บาท

-

ปั๊มหอยโข่ง RY 65-40-2000.00 บาท

-

Pump Asphalt / Bitumen HL95-0.60.00 บาท

-

Hopper Screw Pump G50-20.00 บาท

-

Pump Asphalt / Bitumen HL38-0.60.00 บาท

-

ปั๊มเคมี Axial-Flowing HZW0.00 บาท

-

ปั๊มเคมีความหนืดสูง LQB-18/0.80.00 บาท

-

Petrochemical Process Pump DCZ0.00 บาท

-

ปั๊มหอยโข่ง 50FSB-300.00 บาท

-

ปั๊มหอยโข่งสำหรับสูบน้ำเสีย W-80.00 บาท

-

Lobe Pump 3RP-800.00 บาท

-

แผ่นปูพื้นสำเร็จรูป สแตนเลส 3040.00 บาท

-

Centrifugal Chemical Pump 80FSB-400.00 บาท

-

Roots oil pump ความหนืดสูง LC-38/0.60.00 บาท

-

ปั๊มน้ำโรงงานน้ำตาล IHH, IHK0.00 บาท

-

ปั๊มหอยโข่ง hot oil pump RY15-15-1000.00 บาท

-

ปั๊มเคมีอุตสาหกรรม DFCZ0.00 บาท

-

Vertical Chemical Pump DFLH0.00 บาท

-

Hopper Screw Pump G105-10.00 บาท

-

ปั๊มเคมี Petrochemical Pump DFGY0.00 บาท

-

Self-priming Pump 80FZB-45L0.00 บาท

-

Centrifugal Chemical Pump 25FSB-250.00 บาท

-

Slurry Pump UHB-ZK150/250-300.00 บาท

-

Lobe Pump With Cone Reducer 3RP-500.00 บาท

-

ปั๊มเคมี Horizontal ZE0.00 บาท

-

Food Grade Rotary Lobe Pump 3RP-100A0.00 บาท

-

ปั๊มหอยโข่งสแตนเลส IH25-25-2500.00 บาท

-

ปั๊มมัลติสเตจ D6-25-90.00 บาท

-

TMX Self-priming Magnetic Drive Pump0.00 บาท

-

Magnetic Pump CQB100-80-160FD0.00 บาท

-

Hopper Screw Pump G20-20.00 บาท

-

ปั๊มหอยโข่งพลาสติก 65FSB-32L0.00 บาท

-

Hopper Screw Pump G35-10.00 บาท

-

Hopper Screw Pump G135-10.00 บาท

-

ปั๊มหอยโข่ง RY 25-25-1600.00 บาท

-

ปั๊มเคมี magnetic drive SX-452H0.00 บาท

-

ปั๊มเคมี Slurry Pump AH0.00 บาท

-

Pump Bitumen & Asphalt CBN-70.00 บาท

-

ปั๊มท่อส่งน้ำมัน Dfmsd พร้อมทั้งชุด0.00 บาท

-

Slurry Pump UHB-ZK65/30-500.00 บาท

-

High Temperature Gear Pump 2CG-290.00 บาท

-

Daily Chemicals Transfer Pump 3RP-320.00 บาท

-

ปั๊มเคมี Chemical Pump SGX0.00 บาท

-

สแตนเลสปูพื้นทางเดิน0.00 บาท

-

KCB Gear Pump Model KCB-12000.00 บาท

-

ปั๊มเกียร์สแตนเลสแบบพกพา WCB-30P0.00 บาท

-

API 610 Between Bearing Pump(HBD)0.00 บาท

-

ปั๊มเคมี Chemical Pump DFCZ0.00 บาท

-

KCB ปั๊มเกียร์ รุ่น KCB-18.30.00 บาท

-

Plunger Metering Pump SJ0.00 บาท

-

Bitumen Jacketed Asphalt Pump NYP52A0.00 บาท

-

ปั๊มไดอะแฟรมแบบใช้ไฟฟ้า SKD-320.00 บาท

-

Hopper Screw Pump G40-20.00 บาท

-

Internal Gear Pump NYP7.0A0.00 บาท

-

ปั๊มเคมี Vertical Chemical Pump DFLH0.00 บาท

-

Self Priming Pump 2BEX0.00 บาท

-

ปั๊มเกียร์ stainless steel YCB50-0.60.00 บาท

-

ปั๊มเกียร์สแตนเลสแบบพกพา WCB-1000.00 บาท

-

Centrifugal Chemical Pump 80FSB-250.00 บาท

-

Internal Gear Pump NYP2200.00 บาท

-

Fluoroplastics Liner Pump IHF0.00 บาท

-

ปั๊มโรตารี่ For Asphalt LCXW-10/0.60.00 บาท

-

Self-priming Pump 50ZMD-32F0.00 บาท

-

Lobe Pump พร้อมเครื่องบรรจุ 3RP-1250.00 บาท

-

Food Grade Rotary Lobe Pump 3RP-320.00 บาท

-

Magnetic pump CQB50-32-160FD0.00 บาท

-

Slag Oil Pump ZYB7/0.60.00 บาท

-

ปั๊มเกียร์น้ำมัน KCB2000.00 บาท

-

Heat Jacket Gear Pump RCB-450.00 บาท

-

ปั๊มหอยโข่ง RY 80-50-2500.00 บาท

-

Self-priming Pump 25FZB-20L0.00 บาท

-

ปั๊มเกียร์น้ำมัน KCB18.30.00 บาท

-

Slurry Pump UHB-ZK80/50-200.00 บาท

-

ปั๊มหอยโข่งสแตนเลส IH40-32-1250.00 บาท

-

ปั๊มเคมีความหนืดสูง LQB-58/0.80.00 บาท

-

Landing valve F25-650.00 บาท

-

ปั๊มเกียร์น้ำมัน KCB16000.00 บาท

-

ปั๊มเกียร์น้ำมัน KCB33.30.00 บาท

-

KCB ปั๊มเกียร์ รุ่น KCB-33.30.00 บาท

-

ปั๊มหอยโข่ง RY 100-65-200C0.00 บาท

-

ปั๊มหอยโข่งพลาสติก 40FSB-30L0.00 บาท

-

ปั๊มหอยโข่ง RY 80-50-200B0.00 บาท

-

Gear Pump Bitumen / Asphalt LCB4/0.60.00 บาท

-

Hopper Screw Pump G70-10.00 บาท

-

ปั๊มมัลติสเตจ D6-25-40.00 บาท

-

ปั๊ม Axial Mixed Flowing HQ0.00 บาท

-

Lobe Pump พร้อมเครื่องบรรจุ 3RP-800.00 บาท

-

Self-priming Pump 80FZB-45L0.00 บาท

-

ปั๊มไดอะแฟรม Diaphragm Pump0.00 บาท

-

ปั๊มหอยโข่ง RY 65-40-250A0.00 บาท

-

ปั๊มหอยโข่งเคมีแนวตั้ง0.00 บาท

-

ปั๊มไดอะแฟรมนิวเมติก SKQ-800.00 บาท

-

Pneumatic diaphragm pump SKQ-06/100.00 บาท

-

Plastics Self-Priming Pump 32FZB-200.00 บาท

-

ปั๊มหอยโข่ง 40FSB-200.00 บาท

-

ปั๊มท่อปิโตรเคมี Dfgy0.00 บาท

-

ปั๊มระบบหมุนเวียนน้ำร้อน XS0.00 บาท

-

ปั๊มหอยโข่ง / ปั๊มเคมีสแตนเลส SIH0.00 บาท

-

Magnetic Drive Pump SX-4400.00 บาท

-

KCB Gear Pump Model KCB-25000.00 บาท

-

ปั๊มเกียร์ Gear Pump KCB-28500.00 บาท

-

ปั๊มเคมี Magnetic drive pump MPH-4550.00 บาท

-

ปั๊มเกียร์ Gear Pump KCB-41000.00 บาท

-

Slag Oil Pump ZYB30/0.60.00 บาท

-

ปั๊มเคมี Small Flow SGX0.00 บาท

-

ปั๊มน้ำหอยโข่งแบบแนวนอน0.00 บาท

-

ปั๊มเกียร์ Gear Pump KCB-54000.00 บาท

-

Asphalt Pump with jacket RCB3/0.60.00 บาท

-

Self-priming Pump 80ZMD-32F0.00 บาท

-

ปั๊มหอยโข่งสแตนเลส IH50-32-2000.00 บาท

-

ปั๊มเคมี Horizontal IHK500.00 บาท

-

High Temperature Gear Pump 2CG-1.50.00 บาท

-

ปั๊มหอยโข่ง 40FSB-15(D)0.00 บาท

-

ปั๊มหอยโข่ง Self-priming 25ZX3.2-200.00 บาท

-

Chemical Pump FYH 80FYH-250.00 บาท

-

SJ41F-10C Fluorine lined Sight Glass0.00 บาท

-

ปั๊มเกียร์น้ำมัน KCB12000.00 บาท

-

Electric Diaphragm Pump SKD-650.00 บาท

-

ปั๊มเคมีความหนืดสูง LQB-8/0.360.00 บาท

-

ปั๊มหอยโข่ง RY 100-65-200B0.00 บาท

-

ปั๊มหอยโข่ง RY 100-65-250A0.00 บาท

-

Slag Oil Pump ZYB38/0.40.00 บาท

-

Asphalt Pump with jacket RCB3.3/0.60.00 บาท

-

Self-priming Pump 100FZB-30L0.00 บาท

-

Centrifugal Chemical Pump 80FSB-250.00 บาท

-

ปั๊มไดอะแฟรมสแตนเลส Zero leakage0.00 บาท

-

Lobe Pump พร้อมเครื่องบรรจุ 3RP-250.00 บาท

-

ปั๊มเคมี Slurry Pump DFHH0.00 บาท

-

Three-Screw Pump0.00 บาท

-

ปั๊มเคมี Bitumen / Asphalt NYP2200.00 บาท

-

Pump Asphalt / Bitumen HL150-0.60.00 บาท

-

LPG Transfer Pump YQB25-50.00 บาท

-

Condensate Pump Model N0.00 บาท

-

Slurry Pump UHB-ZK65/25-800.00 บาท

-

ปั๊มเคมี Bitumen / Asphalt NYP7270.00 บาท

-

Slurry Pump UHB-ZK80/50-800.00 บาท

-

ปั๊มเคมี Mixed Flow SPP0.00 บาท

-

ปั๊มเคมี Double Suction DFSJH0.00 บาท

-

Gear Pump Bitumen / Asphalt LCB7/1.00.00 บาท

-

ปั๊มเกียร์สแตนเลสแบบพกพา WCB-75P0.00 บาท

-

ปั๊มมัลติสเตจ D6-25-60.00 บาท

-

Self-priming Pump 65ZMD-32F0.00 บาท

-

Petrochemical Process Pump (OH1) OHF0.00 บาท

-

ปั๊มหอยโข่ง RY 32-32-1600.00 บาท

-

ปั๊มหอยโข่ง 80FSB-30(D)0.00 บาท

-

ปั๊มเกียร์ภายใน Sumitomo QT23-50.00 บาท

-

ปั๊มหอยโข่ง Self-priming 25ZX3.2-320.00 บาท

-

ปั๊มเกียร์น้ำมัน KCB6330.00 บาท

-

ปั๊มหอยโข่ง RY 32-32-2000.00 บาท

-

ปั๊มเคมี IHH, IHK0.00 บาท

-

ปั๊มหอยโข่ง Plastic 80FSB-25L0.00 บาท

-

ปั๊มหอยโข่ง RY 80-50-315A0.00 บาท

-

ปั๊มหอยโข่ง 50FSB-250.00 บาท

-

ปั๊มน้ำหอยโข่ง Self-priming 5HP0.00 บาท

-

Electric Diaphragm Pump SKD-50A0.00 บาท

-

ปั๊มหอยโข่ง self-priming 150CYZ-A-800.00 บาท

-

Slurry Pump UHB-ZK40/10-200.00 บาท

-

High Temperature Gear Pump 2CG-50.00 บาท

-

ปั๊มโรเตอร์ความหนืดสูง NCB18/0.70.00 บาท

-

Centrifugal Chemical Pump 40FSB-150.00 บาท

-

Roots oil pump ความหนืดสูง LC-80/0.60.00 บาท

-

Self-priming Pump 40FZB-200.00 บาท

-

Roots oil pump ความหนืดสูง LC-18/0.60.00 บาท

-

Centrifugal Chemical Pump 50FSB-300.00 บาท

-

Slurry Pump UHB-ZK50/20-300.00 บาท

-

Gear Pump Bitumen / Asphalt LCB4/1.00.00 บาท

-

ปั๊มหอยโข่ง Self-priming 40ZX10-400.00 บาท

-

ปั๊มเกียร์น้ำมัน KCB3000.00 บาท

-

ปั๊มเกียร์ภายใน bitumen & asphalt0.00 บาท

-

Magnetic Pump CQB50-32-125FD0.00 บาท

-

Slurry Pump UHB-ZK100/100-400.00 บาท

-

Petrochemical process pump OHF(OH1)0.00 บาท

-

ปั๊มเกียร์สแตนเลส YCB0.6-1.60.00 บาท

-

Plastics Self-Priming Pump 50FZB-200.00 บาท

-

ปั๊มหอยโข่งสำหรับสารเคมี0.00 บาท

-

ปั๊มเคสแยกแบบแนวนอน XS700-8000.00 บาท

-

ปั๊มหอยโข่ง self-priming 200CYZ-A-630.00 บาท

-

ปั๊มหอยโข่งสแตนเลส IH50-32-2500.00 บาท

-

ปั๊มเคมี Chemical Pump DFCZ0.00 บาท

-

Internal Gear Pump NYP0.00 บาท

-

ปั๊มเกียร์ภายใน NYP0.780.00 บาท

-

Plunger Metering Pump SJ0.00 บาท

-

ปั๊มเคมี Chemical Pump DFCZ0.00 บาท

-

Chemical Pump 50FYH-250.00 บาท

-

Electric Diaphragm Pump SKD-1000.00 บาท

-

Self-priming Pump 80ZMD-45F0.00 บาท

-

Self-priming Pump 50FZB-30L0.00 บาท

-

ปั๊มหอยโข่ง self-priming 150CYZ-A-450.00 บาท

-

Internal Gear Pump NYP7270.00 บาท

-

Heavy Slurry Pump 4/3C-ZA0.00 บาท

-

Lobe Pump พร้อมเครื่องบรรจุ 3RP-1000.00 บาท

-

YQB pump YQB2-50.00 บาท

-

ปั๊มเกียร์ stainless steel YCB20-0.60.00 บาท

-

Lobe Pump With Cone Reducer 3RP-500.00 บาท

-

Self-priming Pump 65ZMD-45F0.00 บาท

-

Self-priming Pump 50FZB-200.00 บาท

-

Heavy Slurry Pump ZA(R)0.00 บาท

-

Magnetic Centrifugal Pump IMD0.00 บาท

-

ปั๊มเคมีความหนืดสูง LQB-29/0.80.00 บาท

-

Lobe Pump 3RP-250.00 บาท

-

ปั๊มโรเตอร์ความหนืดสูง NCB12/0.50.00 บาท

-

ปั๊มไดอะแฟรมขับเคลื่อนไฟฟ้า SKDH-800.00 บาท

-

Chemical Centrifugal Pump ICP0.00 บาท

-

Tandem metering pump0.00 บาท

-

ปั๊มหอยโข่งดูดคู่ DFSS0.00 บาท

-

Hopper Screw Pump G50-10.00 บาท

-

Lobe Pump With Cone Reducer 3RP-1000.00 บาท

-

ปั๊มหอยโข่งสแตนเลส IH25-25-1250.00 บาท

-

Plastics Self-Priming Pump 40FZB-300.00 บาท

-

Pump Bitumen & Asphalt CBN-40.00 บาท

-

ปั๊มหอยโข่ง RY 50-32-250A0.00 บาท

-

Hopper Screw Pump G30-20.00 บาท

-

ปั๊มเกียร์ Gear Pump KCB-76000.00 บาท

-

ปั๊มหอยโข่ง RY 100-65-315A0.00 บาท

-

Slurry Pump UHB-ZK50/20-200.00 บาท

-

ปั๊มหอยโข่ง 80FSB-200.00 บาท

-

Self-priming Pump 100FZB-30L0.00 บาท

-

Self-priming Pump 60FZB-30L0.00 บาท

-

Self-priming Pump 65FZB-70L0.00 บาท

-

Centrifugal Chemical Pump 50FSB-200.00 บาท

-

Magnetic Drive Pump CNA40-250A0.00 บาท

-

ปั๊มหอยโข่งเคมีใบพัดปิด IHH0.00 บาท

-

ปั๊มไดอะแฟรมนิวเมติก SKQ-400.00 บาท

-

Plastic Centrifugal Pump 50FSB-20D0.00 บาท

-

ปั๊มหอยโข่ง RY 80-50-2000.00 บาท

-

Hopper Screw Pump G135-20.00 บาท

-

Hopper Screw Pump G25-20.00 บาท

-

ปั๊มหอยโข่ง RY 100-65-2000.00 บาท

-

ปั๊มเคมีพลาสติกฟลูออรีน CQB15-15-65F0.00 บาท

-

ปั๊มหอยโข่ง RY 100-65-3150.00 บาท

-

Pneumatic Diaphragm Pump0.00 บาท

-

ปั๊มหอยโข่ง RY 50-32-200A0.00 บาท

-

Food Grade Rotary Lobe Pump 3RP-400.00 บาท

-

Pump Asphalt / Bitumen HL72-0.60.00 บาท

-

ปั๊มหอยโข่งสแตนเลส IH40-32-2500.00 บาท

-

Lobe Pump 3RP-100A0.00 บาท

-

ปั๊มเคมี Long Shaft SHY0.00 บาท

-

Plastic Centrifugal Pump 25FSB-25D0.00 บาท

-

ปั๊มเคมี Small-Flux SGX0.00 บาท

-

Slurry Pump UHB-ZK80/50-300.00 บาท

-

Centrifugal Chemical Pump 80FSB-400.00 บาท

-

สแตนเลสแบน 304 แผ่นปูพื้นสำเร็จรูป0.00 บาท

-

Gear Pump Bitumen / Asphalt LCB5/0.60.00 บาท

-

Pump Asphalt / Bitumen HL29-0.60.00 บาท

-

ปั๊มโรตารี่ For Asphalt LCT-50/0.60.00 บาท

-

Self-priming Pump 50ZMD-45F0.00 บาท

-

ปั๊มเคมี Condensate Pump N0.00 บาท

-

ปั๊มหอยโข่ง RY 100-65-200A0.00 บาท

-

ปั๊มเคมี Single Stage DFCZ0.00 บาท

-

Self-priming Pump 50FZB-200.00 บาท

-

ปั๊มหอยโข่ง self-priming 150CYZ-A-550.00 บาท

-

ปั๊ม Axial Mixed Flowing ZQ0.00 บาท

-

KCB Gear Pump Model KCB-16000.00 บาท

-

Pump Asphalt / Bitumen HL108-0.60.00 บาท

-

Self-priming Pump 80ZMD-45F0.00 บาท

-

ปั๊มเกียร์ stainless steel YCB40-0.60.00 บาท

-

ปั๊มหอยโข่งเคมี IHF40-32-1250.00 บาท

-

ปั๊มเคมีพลาสติกฟลูออรีน CQB16-12-50F0.00 บาท

-

ตลับกรองไฟฟ้า PFG-2180.00 บาท

-

ปั๊มหอยโข่ง 40FSB-300.00 บาท

-

ปั๊มหอยโข่งสแตนเลสแนวนอน DS25-10.00 บาท

-

Daily Chemicals Transfer Pump 3RP-500.00 บาท

-

Hopper Screw Pump G105-20.00 บาท

-

ปั๊มมัลติสเตจ D6-25-110.00 บาท

-

Slag Oil Pump ZYB13/0.60.00 บาท

-

Hopper Screw Pump G25-10.00 บาท

-

Lobe Pump พร้อมเครื่องบรรจุ 3RP-650.00 บาท

-

ปั๊มไดอะแฟรมขับเคลื่อนไฟฟ้า SKDH-1250.00 บาท

-

ปั๊มหอยโข่ง 25FSB-180.00 บาท

-

ปั๊มเคมี Horizontal Slurry AH0.00 บาท

-

ปั๊มเคมี สแตนเลส DFLH DHWH0.00 บาท

-

ปั๊มไดอะแฟรมขับเคลื่อนไฟฟ้า SKDH-1000.00 บาท

-

Plastics Self-Priming Pump 25FZB-200.00 บาท

-

ปั๊มหอยโข่ง self-priming 150CYZ-A-650.00 บาท

-

Daily Chemicals Transfer Pump 3RP-650.00 บาท

-

ปั๊มหอยโข่ง 50FSB-30(D)0.00 บาท

-

Internal Gear Pump NYP111A0.00 บาท

-

Self-priming Pump 40FZB-30L0.00 บาท

-

ปั๊มเคมีความหนืดสูง LQB-29/0.360.00 บาท

-

Hopper Screw Pump G40-10.00 บาท

-

Self-priming Pump 80FZB-30L0.00 บาท

-

Hopper Screw Pump G25-20.00 บาท

-

PP Magnetic Drive Pump PVDF-20R(M)0.00 บาท

-

ปั๊มเกียร์สแตนเลส YCB4-1.60.00 บาท

-

Hopper Screw Pump G35-20.00 บาท

-

ปั๊มหอยโข่ง RY 50-32-2000.00 บาท

-

ปั๊มเกียร์สแตนเลสแบบพกพา WCB-50P0.00 บาท

-

ปั๊มเคมีสแตนเลส CQ40-25-2000.00 บาท

-

KCB ปั๊มเกียร์ รุ่น KCB-3000.00 บาท

-

ปั๊มเกียร์สแตนเลส YCB1.6-0.60.00 บาท

-

High-pressure Pumps SHP0.00 บาท

-

Stainless Steel Pump DFWH0.00 บาท

-

Hopper Screw Pump G40-20.00 บาท

-

Self-priming Pump 65FZB-70L0.00 บาท

-

Hopper Screw Pump G30-10.00 บาท

-

High Temperature Gear Pump 2CG-10.00 บาท

-

Slurry Pump UHB-ZK125/140-280.00 บาท

-

ปั๊มหอยโข่งเคมี IHF32-25-1250.00 บาท

-

ปั๊มหอยโข่ง RY 100-65-2500.00 บาท

-

ปั๊มเคมีไหลตามแนวแกน HZW0.00 บาท

-

Self-priming Pump 50FZB-45L0.00 บาท

-

ปั๊มเคมี Oil Pump DFAY0.00 บาท

-

ปั๊มไดอะแฟรมขับเคลื่อนไฟฟ้า SKDH-80A0.00 บาท

-

Landing valve F26-650.00 บาท

-

Pneumatic Diaphragm Pump0.00 บาท

-

Slurry Pump UHB-ZK200/400-250.00 บาท

-

Chemical Pump FYH 25FYH-250.00 บาท

-

ปั๊มเกียร์สแตนเลส PEEK gears0.00 บาท

-

ปั๊มเคมีความหนืดสูง LQB-38/0.80.00 บาท

-

ปั๊มโรตารี่ For Asphalt LCT-100/0.60.00 บาท

-

ปั๊มหอยโข่ง RY 65-40-2500.00 บาท

-

ปั๊มหอยโข่งสแตนเลสแนวนอน DS40-20.00 บาท

-

ปั๊มไดอะแฟรมแบบใช้ไฟฟ้า SKD-100.00 บาท

-

ปั๊มเคมี Horizontal DFZA0.00 บาท

-

ปั๊มหอยโข่งสแตนเลสแนวนอน DS50-30.00 บาท

-

ปั๊มเกียร์ภายใน Sumitomo QT43-200.00 บาท

-

ปั๊มโรเตอร์ความหนืดสูง NCB20/0.50.00 บาท

-

ปั๊มเกียร์ภายใน Sumitomo QT620.00 บาท

-

Centrifugal Chemical Pump 40FSB-150.00 บาท

-

ปั๊มเคมีสแตนเลส HCZ50-2000.00 บาท

-

ปั๊มหอยโข่งสแตนเลส IH50-32-1250.00 บาท

-

ปั๊มเครื่องสูบน้ำแนวตั้ง0.00 บาท

-

ปั๊มสารเคมี / ปั๊มปิโตรเคมี DFGY-P0.00 บาท

-

Centrifugal Chemical Pump 80FSB-300.00 บาท

-

ปั๊มหอยโข่ง 100FSB-320.00 บาท

-

ปั๊มเคมี Chemical Pump DFZE0.00 บาท

-

Magnetic Centrifugal Pump IMD0.00 บาท

-

ปั๊มหอยโข่ง RY 20-20-1250.00 บาท

-

Daily Chemicals Transfer Pump 3RP-800.00 บาท

-

ปั๊มหอยโข่งเคมีแนวนอน IHH0.00 บาท

-

ปั๊มหอยโข่งสแตนเลส IH25-25-1600.00 บาท

-

ปั๊มเคมี Magnetic Pump CQ0.00 บาท

-

YQB pump YQB5-50.00 บาท

-

ตลับกรองไฟฟ้า PFG-2120.00 บาท

-

Slurry Pump UHB-ZK65/30-300.00 บาท

-

YQB pump YQB10-5A0.00 บาท

-

Roots oil pump ความหนืดสูง LC-10/0.60.00 บาท

-

ปั๊มหอยโข่ง hot oil pump RY20-20-1250.00 บาท

-

ปั๊มเคมีหอยโข่งแนวนอน IHH0.00 บาท

-

Self-priming Pump 80FZB-70L0.00 บาท

-

Internal Gear Pump NYP240.00 บาท

-

ปั๊มหอยโข่งสแตนเลสแนวนอน DS40-30.00 บาท

-

ปั๊มโรเตอร์ความหนืดสูง NCB1.8/0.30.00 บาท

-

ปั๊มเคมี Stainless Steel DFWH0.00 บาท

-

Centrifugal Chemical Pump 65FSB-320.00 บาท

-

ปั๊มหอยโข่ง RY 125-100-2500.00 บาท

-

ปั๊มเคมีความหนืดสูง LQB-8/0.80.00 บาท

-

ปั๊มเคมี Chemical Pump DFLPH0.00 บาท

-

ปั๊มหอยโข่งเคมี IHF32-25-125A0.00 บาท

-

ปั๊มหอยโข่ง RY 150-150-2000.00 บาท

-

ปั๊มหอยโข่ง 80FSB-250.00 บาท

-

Self-priming Pump 65FZB-45L0.00 บาท

-

Resin loading pump0.00 บาท

-

ปั๊มหอยโข่ง RY 65-50-1600.00 บาท

-

KCB ปั๊มเกียร์ รุ่น KCB-83.30.00 บาท

-

Magnetic Pump CQB50-32-160FD0.00 บาท

-

Internal Gear Pump NYP6500.00 บาท

-

Centrifugal Chemical Pump 100FSB-320.00 บาท

-

ปั๊มเคมี Chemical Pump IHH0.00 บาท

-

Horizontal Chemical Pump DFCZ0.00 บาท

-

Centrifugal Chemical Pump 80FSB-200.00 บาท

-

ปั๊มเคมี Chemical Pump DFWH0.00 บาท

-

Magnetic Pump ZCQ40-32-1250.00 บาท

-

High Temperature Gear Pump 2CG-380.00 บาท

-

Daily Chemicals Transfer Pump 3RP-400.00 บาท

-

Pump Bitumen & Asphalt CBN-600.00 บาท

-

ปั๊มเกียร์สแตนเลส YCB8-0.60.00 บาท

-

ปั๊มน้ำมันร้อน0.00 บาท

-

Daily Chemicals Transfer Pump 3RP-500.00 บาท

-

Centrifugal Chemical Pump 40FSB-300.00 บาท

-

ปั๊มหอยโข่ง RY 80-50-250A0.00 บาท

-

พื้นโรงงาน สแตนเลส เกรด 3040.00 บาท

-

Daily Chemicals Transfer Pump 3RP-320.00 บาท

-

Asphalt Pump with jacket RCB1/0.60.00 บาท

-

Condensate Water Pump NW0.00 บาท

-

ปั๊มเคมี magnetic drive SX-453H0.00 บาท

-

Hopper Screw Pump G50-20.00 บาท

-

ปั๊มหอยโข่ง RY 20-20-1000.00 บาท

-

ปั๊มเคมีแรงดันสูง DFZWL0.00 บาท

-

Internal Gear Pump NYP520.00 บาท

-

ปั๊มเคมีสแตนเลส CQ40-25-1600.00 บาท

-

ปั๊มไดอะแฟรมนิวเมติก SKQ-500.00 บาท

-

Magnetic Drive Pump CN0.00 บาท

-

ปั๊มเกียร์น้ำมัน KCB1350.00 บาท

-

พื้นอาคาร สเตนเลส เกรด 3040.00 บาท

-

ปั๊มเคมี Magnetic drive pump MPH-5650.00 บาท

-

ปั๊มลูกสูบแรงดันสูง SHP200.00 บาท

-

Special sulfur heat metering pump0.00 บาท

-

Self-priming Pump 65ZMD-45F0.00 บาท

-

ปั๊มสูบหอยโข่งเดี่ยว XA0.00 บาท

-

Self-priming Pump 80FZB-30L0.00 บาท

-

Magnetic pump CQB50-32-125FD0.00 บาท

-

ปั๊มหอยโข่ง 40FSB-150.00 บาท

-

Slurry Pump UHB-ZK40/10-200.00 บาท

-

ปั๊มเกียร์เคมีสแตนเลส 20SKCQB-150.00 บาท

-

Slurry Pump UHB-ZK65/30-200.00 บาท

-

ปั๊มเคมีความหนืดสูง LQB-12/0.360.00 บาท

-

ปั๊มโรเตอร์ความหนืดสูง NCB3/0.30.00 บาท

-

ปั๊มเคมี Slurry Pump AH0.00 บาท

-

Gear Pump Bitumen / Asphalt LCB3/0.60.00 บาท

-

ปั๊มเคมี Horizontal IHF500.00 บาท

-

Magnetic Drive Pump SX-4520.00 บาท

-

ปั๊มหอยโข่งเคมี IHF32-25-1600.00 บาท

-

ปั๊มเคมีความหนืดสูง LQB-38/0.360.00 บาท

-

Hopper Screw Pump G40-10.00 บาท

-

ปั๊มหอยโข่งสแตนเลสแนวนอน DS25-1 / 20.00 บาท

-

Slurry Pump UHB-ZK50/20-200.00 บาท

-

ปั๊มโรเตอร์ความหนืดสูง NCB16/0.50.00 บาท

-

YQB pump YQB15-5A0.00 บาท

-

Hopper Screw Pump G35-10.00 บาท

-

ปั๊มเกียร์น้ำมัน KCB550.00 บาท

-

ปั๊มเคมี Horizontal ZA0.00 บาท

-

Lobe Pump พร้อมเครื่องบรรจุ 3RP-320.00 บาท

-

Three-spindle Screw Pump SM0.00 บาท

-

ปั๊มแรงดันน้ำพร้อมปั๊มดูดคู่ XS0.00 บาท

-

ปั๊มหอยโข่ง hot oil pump RY40-25-1600.00 บาท

-

Self-priming Pump 50FZB-70L0.00 บาท

-

YQB pump YQB15-50.00 บาท

-

พื้นโรงงาน สเตนเลส เกรด 3040.00 บาท

-

Lobe Pump With Cone Reducer 3RP-650.00 บาท

-

Internal Gear Pump NYP800.00 บาท

-

Centrifugal Chemical Pump 65FSB-320.00 บาท

-

Slurry Pump UHB-ZK100/60-500.00 บาท

-

ปั๊มเกียร์ stainless steel YCB10-1.60.00 บาท

-

Between Bearing Pump API610 HBR0.00 บาท

-

ปั๊มเกียร์ภายใน Sumitomo QT420.00 บาท

-

Slag Oil Pump ZYB60/0.40.00 บาท

-

ปั๊มไดอะแฟรมนิวเมติก0.00 บาท

-

ปั๊มเกียร์ stainless steel YCB80-0.60.00 บาท

-

ปั๊มหอยโข่งสแตนเลส IH50-32-1600.00 บาท

-

Hopper Screw Pump G25-10.00 บาท

-

Hopper Screw Pump G35-20.00 บาท

-

Centrifugal Chemical Pump 50FSB-200.00 บาท

-

ปั๊มเกียร์ภายใน Sumitomo Q23-40.00 บาท

-

Lobe Pump With Cone Reducer 3RP-400.00 บาท

-

Slag Oil Pump ZYB18/1.00.00 บาท

-

ปั๊มลม AODD รุ่น SK-400.00 บาท

-

Hopper Screw Pump G135-20.00 บาท

-

UHMWPE Plastic Chemical Pump0.00 บาท

-

Plastic Centrifugal Pump 40FSB-20D0.00 บาท

-

ปั๊มเกียร์ Gear Pump KCB-38000.00 บาท

Facebook Comments (

2

ข้อมูล

ข้อมูล