ลงชื่อเข้าใช้

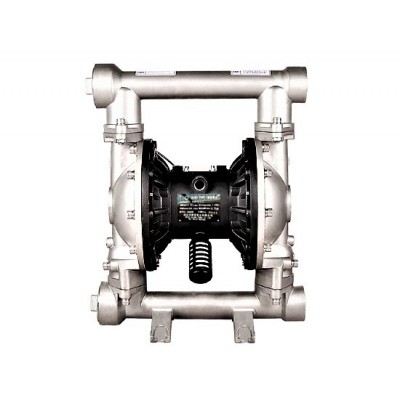

ICP Series Chemical Centrifugal Pump

Product Description

- ICP series chemical centrifugal pumps are newly developed by integrating the chemical pump structures of several domestic and

foreign pump companies. It’s interchangeable with IH series pumps and CZ series chemical pumps from Switzerland Sulzer

Company, and its operational reliability is better than IH and CZ series pumps.

Application

- According to the different media conveyed by the users, the material of the overcurrent components of the pump consists of

fluoroplastic, bismuth glass, various austenitic stainless steel, titanium metal, nickel metal, etc.

- so it can be widely used to transport low temperature, normal temperature or high temperature corrosive medium.

- And allow a certain amount of solid particles, mainly used in chemical, petrochemical, oil refining, metallurgy, light industry,

pharmaceutical and other industrial sectors.

Design Feature

1.Improve the lifespan of mechanical seals and bearings with the highest failur e rate in chemical pump operation.

2. Use thicker shafts to increase shaft stiffness.

3.The bearing is enlarged, and the double-row radial thrust ball bearing is adopted. The axial clearance of the rotor is small, the

lifespan of bearing is larger than 25,000 hours, which prolongs the lifespan of the mechanical seal.

4.The impeller and the pump shaft can be connected by screws, the sealing is reliable, the disassembly and assembly is convenient,

and the anti-cavitation is better than the IH pumps.

5.Available in a variety of shaft seal types: single-end, double-end, internally mounted, externally mounted mechanical seals, cartridge

seals, packing seals, etc., and can be supplied with the mechanical seal auxiliar y system according to the API610 standard.

- ICP series chemical centrifugal pump pdf-1024x768.png)

- ICP series chemical centrifugal pump pdf-1024x768.png)

|

|

ความคิดเห็นเกี่ยวกับตัวสินค้า

ชื่อ:

เขียนความคิดเห็นของคุณ:

รูปภาพ (Upload Multiple images) :

| Review Images | Delete |

วีดีโอ (Enter Youtube video link) :

ให้คะแนน: น้อย

การชำระเงิน |

กรุณาโอนเงินเข้าบัญชี ธนาคาร กสิกรไทย สาขา คลอง 6 ธัญบุรี ชื่อบัญชี บจก.เจช้อปดีแอล เลขที่บัญชี 119-347-595-3 โปรติดต่อฝ่ายขาย 061-5597151 ก่อนการโอน |

|

|

หมายเลขอ้างอิง: 676

ประตูน้ำเหล็กหล่อ : ลิ้นยกแบบรองลิ้นโลหะ สำหรับงานประปา CASR IRON GATE VALVE – METAL SEATED FOR WATER SERVICES MODEL (DN-CI-MS) TIS 256 PN 6, 10, 16 TIS 432 PN 6, 10, 16 DIN 3352 PN 10, 16 BS 5150 PN 6, 10, 16 BS EN 1171 PN 6, 10, 16 Size DN80-1200 mm. ประตูน้ำ (Gate Valve) เหล็กหล่อใต้ดิน ชนิดลิ้นยกแบบรองลิ้นโลหะ มอก.256 ประตูน้ำ (Gate Valve) เหล็กหล่อใต้ดิน ชนิดลิ้นยกแบบรองลิ้นโลหะ สำหรับงานประปา มอก.256 วาล์วได้ผลิตและทดสอบตามมาตรฐาน BS 5150 PN10/16/25, BS EN 1171:2002, BS EN 1074-2, TIS 432 PN 6 / 10 / 16 และสอดคล้องกับข้อกำหนดของ MSS-SP-70 class 125 / 250 ใช้งานได้กับทั้งน้ำ, อากาศและไอน้ำ ตุณลักษณะ - ตัวเรือนเป็นเหล็กหล่อ - ปลายประตูน้ำ สามารถเป็นหน้าจาน, เกลียวและปลายเรียบ - หน้าจานสามารถเจาะให้เข้ากับ ANSI B16.1, ANSI B16.5, BS4504, BS10, BS EN 1092-2, BS 4772, AS2129, DIN, JIS และอื่น ๆ - เลือกตัวขับได้หลากหลาย ตามที่ต้องการเช่น พวงมาลัย, แป้นประแจขันหรือ cap, พวงมาลัยโซ่, เฟืองตรง, เฟืองดอกจอก, นิวเมติก, ไฮดรอลิก และไฟฟ้า

Fire Pump Controller UL FM standard for Jockey Pump Type You have decided to reduce the risk of fire damage to your facility by installing a UL, ULC listed fire pump system. Your next decision is which system to purchase. You want a fire pump that is proven in installations worldwide. Manufactured by an professional with vast experience in the fire protection field. You want complete service to field start-up. You want a Engine Controller Fire Protection UL FM Providing Pumping Solutions TONGKE Can Fulfill Your Requirements: Complete in-house fabrication capabilities Mechanical-run test capabilities with customer furnished equipment for all NFPA standards Horizontal models for capacities to 2,500 gpm Vertical models for capacities to 5,000 gpm In-line models for capacities to 1,500 gpm End suction models for capacities to 1,500 gpm Drives: electric motor or diesel engine Basic units and packaged systems.

กลุ่มผลิตภัณฑ์เดียวกันที่น่าซื้อ

Facebook Comments (

1

ข้อมูล

ข้อมูล