ลงชื่อเข้าใช้

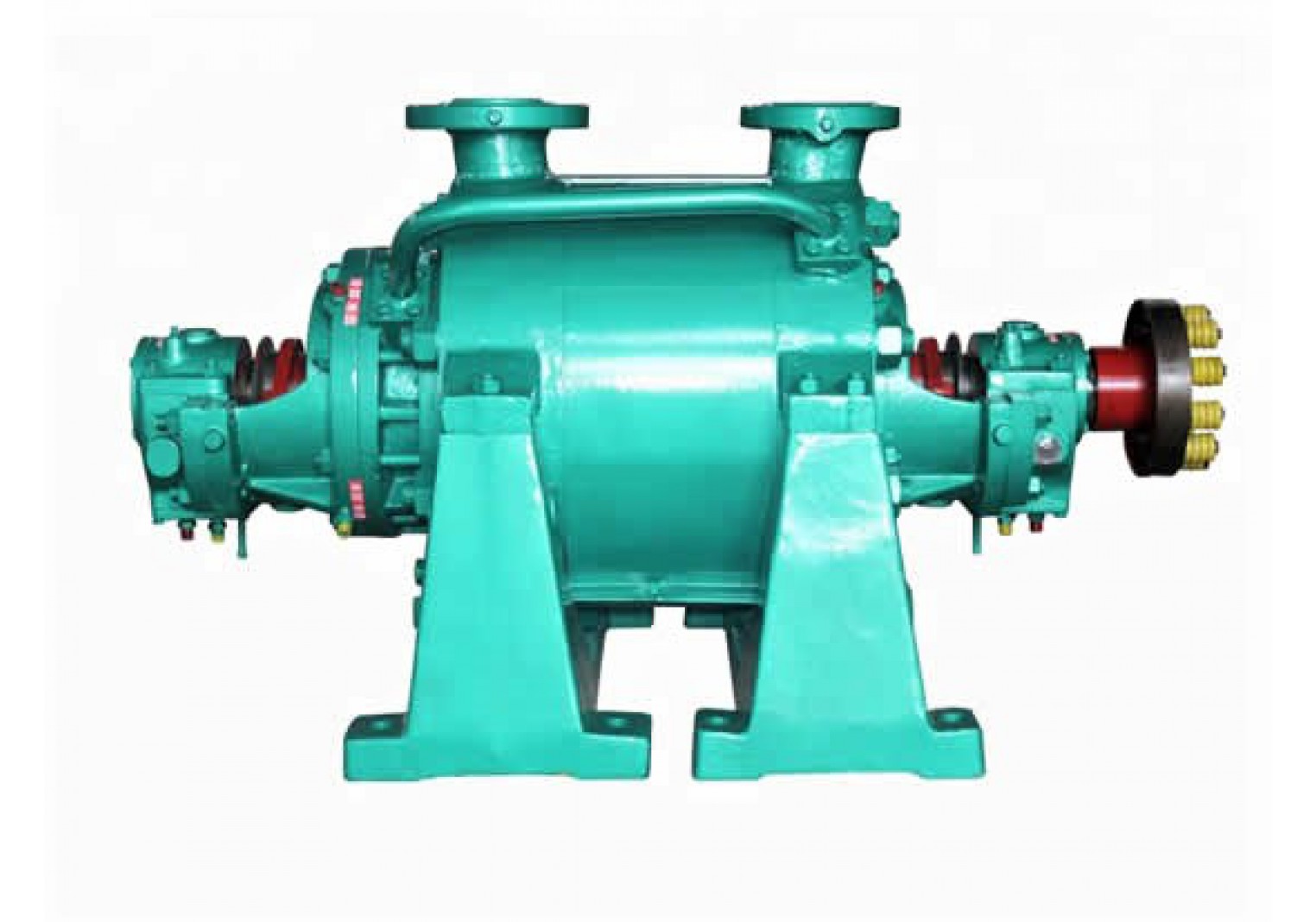

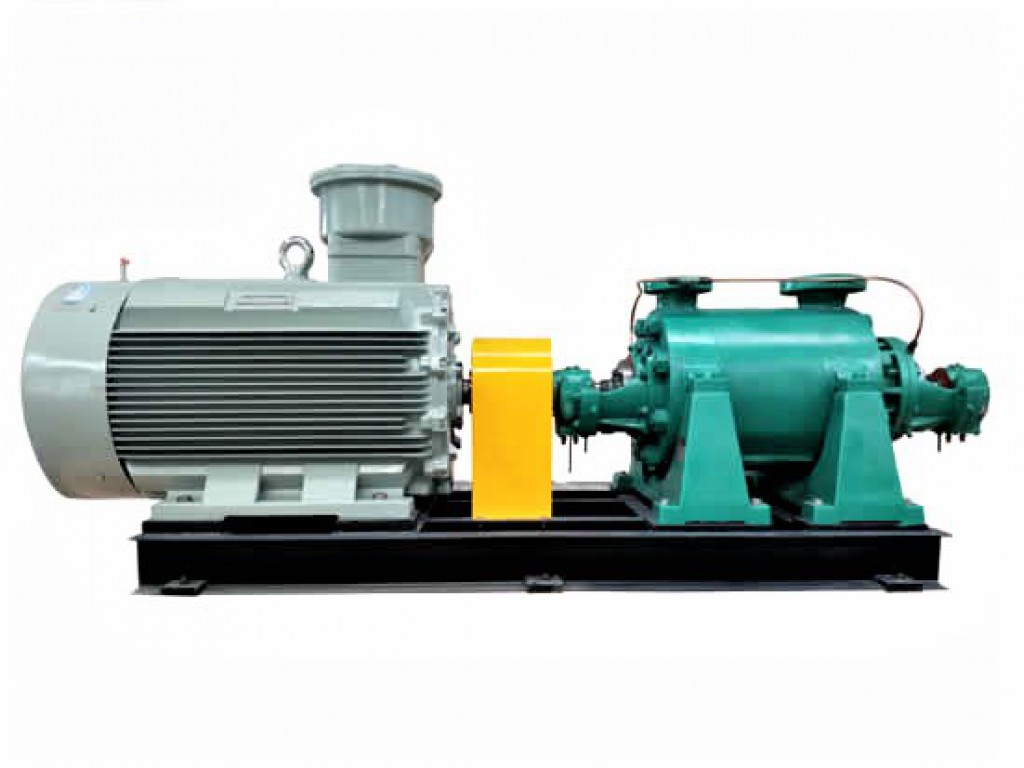

DG45-80 boiler feed water pump

Description

- DG45-80 boiler feed water pump is a horizontal single-suction multi-stage centrifugal pump, used to transport clean

water and liquids with physical and chemical properties similar to water, suitable for medium and low pressure boiler

feed water, and also suitable for high pressure water supply and drainage in factories or cities. The temperature of the

conveying medium is -20°C ~ 150°C, and the inlet allowable pressure is less than 0.6MPA. Due to the advantages

of safe and stable operation, low noise, long life and easy installation and maintenance, it is widely used by power plant

steel mills.

DG45-80 boiler feed pump structure description

- The main parts of the medium and low pressure feed pump (lift 50-684m) are generally made of high-quality cast iron,

and the secondary high pressure feed pump (lift 409-1450m) is made of cast steel or stainless steel.

- The pump casing part is mainly connected by a bearing body, a front section, a middle section, a rear section, a guide

vane, etc., and the center line of the suction port of the front section is perpendicular to the horizontal or horizontal. The

midline spit out in the rear section is perpendicular to the horizontal, and may also be horizontal.

- The rotor part is mainly composed of the shaft and the impeller, shaft sleeve, balance plate and other parts installed on

the shaft. The parts on the shaft are fastened with flat keys and sleeve nuts to make them integrated with the shaft. The

whole rotor is supported on the pump casing by bearings at both ends, and the impeller in the rotor part is determined

according to the number of pump stages. The rotor is driven by the motor. From the motor end, the pump rotates clockwise.

- This type of pump uses rolling bearings, which are not subject to axial forces depending on the model. The pump should

allow the rotor to move axially in the pump housing during operation. Radial ball bearings cannot be used. The bearing is

lubricated with calcium-based butter.

- The front, middle, and rear sections of the pump are sealed with molybdenum disulfide grease. The rotor parts and the

fixed part are sealed by seal rings, guide vane sleeves, packing, etc. When the seal ring and guide vane sleeve are worn

It should be replaced in time if it has affected the operation and performance of the pump.

- This pump adopts packing seal or mechanical seal. Generally, it is better to use mechanical seal when the temperature

exceeds 90 degrees. When using it, the position of the packing and the mechanical seal must be properly secured. The

tightness of the packing and the mechanical seal must be appropriate. It is better to go out.

|

|

ความคิดเห็นเกี่ยวกับตัวสินค้า

ชื่อ:

เขียนความคิดเห็นของคุณ:

รูปภาพ (Upload Multiple images) :

| Review Images | Delete |

วีดีโอ (Enter Youtube video link) :

ให้คะแนน: น้อย

การชำระเงิน |

กรุณาโอนเงินเข้าบัญชี ธนาคาร กสิกรไทย สาขา คลอง 6 ธัญบุรี ชื่อบัญชี บจก.เจช้อปดีแอล เลขที่บัญชี 119-347-595-3 โปรติดต่อฝ่ายขาย 061-5597151 ก่อนการโอน |

|

|

หมายเลขอ้างอิง: 67866

Capacity: 200 GPM – 2000 GPM

Pressures: 40 – 355 psi

Maximum Working Pressures: 290 to 395 PSI

Speed: 1480,1760, 2900,2980, 3000 RPM

Dynamically Balanced Impeller extends bearing life and ensures smoother operation.

Designed and built as per UL 448 AND NFPA20 for maximum reliability.

Constructed in variety of metallurgies.

Available in 50 Hz and 60 Hz.

Drivers with gear boxes at electric and diesel speeds.

Designed for easy maintenance without interfering with piping.

Open line shaft, water lubricated construction for ease of maintenance.

Self-Venting Design eliminates vapor lock and the need for automatic air release valve

ประตูน้ำเหล็กหล่อ : ลิ้นยกแบบรองลิ้นโลหะ สำหรับงานประปา CASR IRON GATE VALVE – METAL SEATED FOR WATER SERVICES MODEL (DN-CI-MS) TIS 256 PN 6, 10, 16 TIS 432 PN 6, 10, 16 DIN 3352 PN 10, 16 BS 5150 PN 6, 10, 16 BS EN 1171 PN 6, 10, 16 Size DN80-1200 mm. ประตูน้ำ (Gate Valve) เหล็กหล่อใต้ดิน ชนิดลิ้นยกแบบรองลิ้นโลหะ มอก.256 ประตูน้ำ (Gate Valve) เหล็กหล่อใต้ดิน ชนิดลิ้นยกแบบรองลิ้นโลหะ สำหรับงานประปา มอก.256 วาล์วได้ผลิตและทดสอบตามมาตรฐาน BS 5150 PN10/16/25, BS EN 1171:2002, BS EN 1074-2, TIS 432 PN 6 / 10 / 16 และสอดคล้องกับข้อกำหนดของ MSS-SP-70 class 125 / 250 ใช้งานได้กับทั้งน้ำ, อากาศและไอน้ำ ตุณลักษณะ - ตัวเรือนเป็นเหล็กหล่อ - ปลายประตูน้ำ สามารถเป็นหน้าจาน, เกลียวและปลายเรียบ - หน้าจานสามารถเจาะให้เข้ากับ ANSI B16.1, ANSI B16.5, BS4504, BS10, BS EN 1092-2, BS 4772, AS2129, DIN, JIS และอื่น ๆ - เลือกตัวขับได้หลากหลาย ตามที่ต้องการเช่น พวงมาลัย, แป้นประแจขันหรือ cap, พวงมาลัยโซ่, เฟืองตรง, เฟืองดอกจอก, นิวเมติก, ไฮดรอลิก และไฟฟ้า

Fire Pump Controller UL FM standard for Jockey Pump Type You have decided to reduce the risk of fire damage to your facility by installing a UL, ULC listed fire pump system. Your next decision is which system to purchase. You want a fire pump that is proven in installations worldwide. Manufactured by an professional with vast experience in the fire protection field. You want complete service to field start-up. You want a Engine Controller Fire Protection UL FM Providing Pumping Solutions TONGKE Can Fulfill Your Requirements: Complete in-house fabrication capabilities Mechanical-run test capabilities with customer furnished equipment for all NFPA standards Horizontal models for capacities to 2,500 gpm Vertical models for capacities to 5,000 gpm In-line models for capacities to 1,500 gpm End suction models for capacities to 1,500 gpm Drives: electric motor or diesel engine Basic units and packaged systems.

กลุ่มผลิตภัณฑ์เดียวกันที่น่าซื้อ

-

ปั๊ม Boiler Feed DG85-80×60.00 บาท

-

Boiler Feed Water Pump0.00 บาท

-

ปั๊ม Boiler Feed DG85-80×50.00 บาท

-

ปั๊มป้อนแรงดันไอน้ำ DG0.00 บาท

-

ปั๊มป้อนหม้อไอน้ำ DG0.00 บาท

-

Boiler Feed Water Pump0.00 บาท

-

API 610 Double Casing Pump(HBB)0.00 บาท

-

Boiler Feed Water Pump0.00 บาท

-

Boiler Feed Water Pump0.00 บาท

Facebook Comments (

2

ข้อมูล

ข้อมูล