ลงชื่อเข้าใช้

Dosing device for pharmaceutical, life sciences and biotechn

Filtration and Other Processes in the Pharmaceutical, Life Sciences, and Biotech Industries

- Our systems have in-house engineering and meet all the industry-relevant requirements, such as for filtration (cGMP, GAMP, 21 CFR, etc.).

We also offer complete documentation, acceptance tests, validation/qualification, installation, and commissioning services.

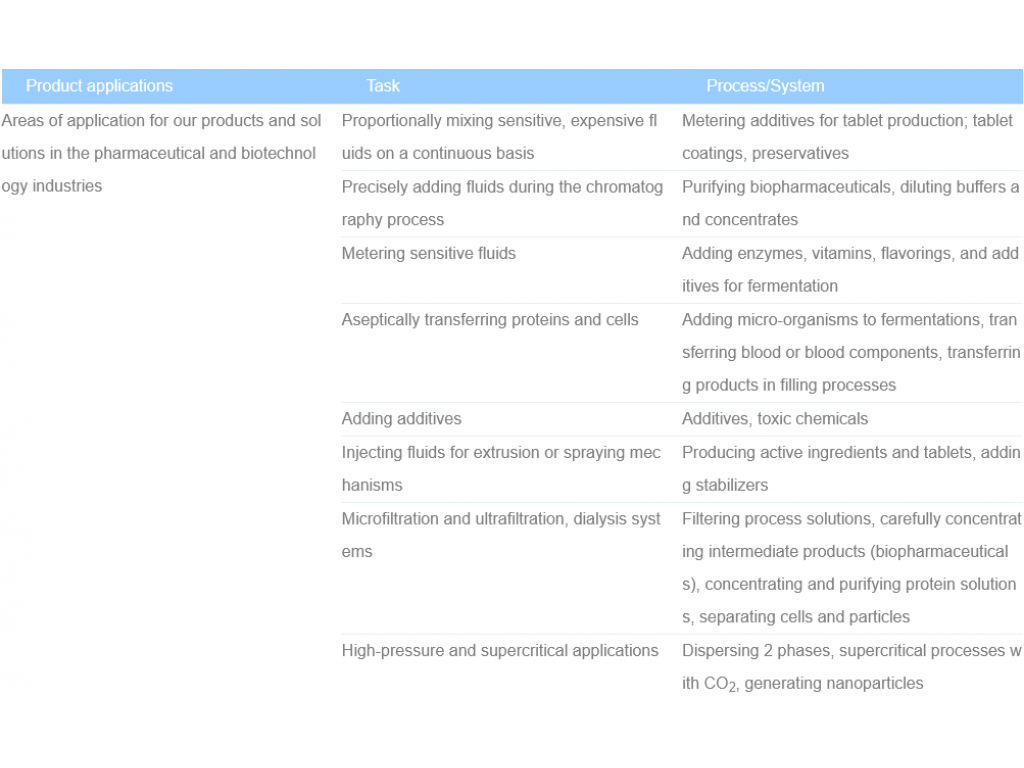

- System solutions from ShenBei can be found in many applications in this market: from the metering of liquids, production of dispersions,

various mixing tasks, filtration processes, the dilution of buffers or concentrates, right through to microfiltration and ultrafiltration systems.

These require precise volume flows and exact conformance with specific process conditions.

Solutions for the Pharmaceutical, Life Sciences, and Biotech Industries

- The biopharmaceutical, fine chemical, veterinary medicine, and special food supplement industries all require systems that are easy to clean

and drain, and that are manufactured and documented according to the applicable guidelines. ShenBei has the expertise to design and construct

customer-specific systems for these industries.

- Our scope of supply for these sectors ranges from simple metering systems for metering additives, process chromatography and buffer dilution

systems, right through to complex systems for the proportional mixing, conveyance, or filtration of various media.

Process-Integrated Pump Systems for Filtration and Other Processes

- We also use the ShenBei intellidrive technology to solve difficult metering and conveying tasks:

1. Applications that allow a minimum of pulsation such as sensitive chromatography media or fluids during filtration processes

2. Highly viscous fluids such as syrup or gel

3. Highly precise metering during filling jobs

4. Hermetically sealed for hygienic and sterile processes

5. Mixing of two fluids in one pump head such as gradient formulation in chromatography processes

6. At varying flow rates and at inhomogeneous qualities, changing pressures, or temperatures

Advantages

- High end pumps, equipment and systems : We deliver high-end pumps integrated into complete systems and units for your specificapplications.

In doing so, we of course rely on the tried-and-tested ShenBei quality.

- Special materials : On request, we can build systems with special materials such as Hastelloy, titanium, duplex stainless steel or further materials.

If you are interested, please contact our product manager.

- Easy to clean : An especially important advantage for pharmaceutical and food industry is that our systems can be quickly and easily cleaned with

cleaning chemicals or hot steam.

- Economic solutions : We always deliver economic pumps, systems and units with minimized energy consumption, high efficiency, low maintenance

and a long lifetime.

- Patented sandwich diaphragm : Our patented diaphragm metering pumps use metal or PTFE sandwich diaphragms with Diaphragm Protection System

(DPS) for maximum operational safety.

- International standards : ShenBei pumps, systems and units are compliant with major international standards such as DVGW G280, WHG, PED, ISO

9001, ASME, ATEX and TA-Luft. Of course, you can also define your own standards.

- Tried and tested modular system : We design our systems and units in modular design with numerous engine and pump head combinations for different

applications.

- Sanitary & hygienic design : Highly polished surfaces and a minimal dead space construction are the basis for a system design that meets all the industry's

hygienic standards.

- Maintenance and service : No matter if maintenance, spare parts or repair - our service technicians are well trained and available worldwide. Thus, we

guarantee fast response and smooth operations.

|

|

ความคิดเห็นเกี่ยวกับตัวสินค้า

ชื่อ:

เขียนความคิดเห็นของคุณ:

รูปภาพ (Upload Multiple images) :

| Review Images | Delete |

วีดีโอ (Enter Youtube video link) :

ให้คะแนน: น้อย

การชำระเงิน |

กรุณาโอนเงินเข้าบัญชี ธนาคาร กสิกรไทย สาขา คลอง 6 ธัญบุรี ชื่อบัญชี บจก.เจช้อปดีแอล เลขที่บัญชี 119-347-595-3 โปรติดต่อฝ่ายขาย 061-5597151 ก่อนการโอน |

|

|

หมายเลขอ้างอิง: 453453

Capacity: 200 GPM – 2000 GPM

Pressures: 40 – 355 psi

Maximum Working Pressures: 290 to 395 PSI

Speed: 1480,1760, 2900,2980, 3000 RPM

Dynamically Balanced Impeller extends bearing life and ensures smoother operation.

Designed and built as per UL 448 AND NFPA20 for maximum reliability.

Constructed in variety of metallurgies.

Available in 50 Hz and 60 Hz.

Drivers with gear boxes at electric and diesel speeds.

Designed for easy maintenance without interfering with piping.

Open line shaft, water lubricated construction for ease of maintenance.

Self-Venting Design eliminates vapor lock and the need for automatic air release valve

ประตูน้ำเหล็กหล่อ : ลิ้นยกแบบรองลิ้นโลหะ สำหรับงานประปา CASR IRON GATE VALVE – METAL SEATED FOR WATER SERVICES MODEL (DN-CI-MS) TIS 256 PN 6, 10, 16 TIS 432 PN 6, 10, 16 DIN 3352 PN 10, 16 BS 5150 PN 6, 10, 16 BS EN 1171 PN 6, 10, 16 Size DN80-1200 mm. ประตูน้ำ (Gate Valve) เหล็กหล่อใต้ดิน ชนิดลิ้นยกแบบรองลิ้นโลหะ มอก.256 ประตูน้ำ (Gate Valve) เหล็กหล่อใต้ดิน ชนิดลิ้นยกแบบรองลิ้นโลหะ สำหรับงานประปา มอก.256 วาล์วได้ผลิตและทดสอบตามมาตรฐาน BS 5150 PN10/16/25, BS EN 1171:2002, BS EN 1074-2, TIS 432 PN 6 / 10 / 16 และสอดคล้องกับข้อกำหนดของ MSS-SP-70 class 125 / 250 ใช้งานได้กับทั้งน้ำ, อากาศและไอน้ำ ตุณลักษณะ - ตัวเรือนเป็นเหล็กหล่อ - ปลายประตูน้ำ สามารถเป็นหน้าจาน, เกลียวและปลายเรียบ - หน้าจานสามารถเจาะให้เข้ากับ ANSI B16.1, ANSI B16.5, BS4504, BS10, BS EN 1092-2, BS 4772, AS2129, DIN, JIS และอื่น ๆ - เลือกตัวขับได้หลากหลาย ตามที่ต้องการเช่น พวงมาลัย, แป้นประแจขันหรือ cap, พวงมาลัยโซ่, เฟืองตรง, เฟืองดอกจอก, นิวเมติก, ไฮดรอลิก และไฟฟ้า

Fire Pump Controller UL FM standard for Jockey Pump Type You have decided to reduce the risk of fire damage to your facility by installing a UL, ULC listed fire pump system. Your next decision is which system to purchase. You want a fire pump that is proven in installations worldwide. Manufactured by an professional with vast experience in the fire protection field. You want complete service to field start-up. You want a Engine Controller Fire Protection UL FM Providing Pumping Solutions TONGKE Can Fulfill Your Requirements: Complete in-house fabrication capabilities Mechanical-run test capabilities with customer furnished equipment for all NFPA standards Horizontal models for capacities to 2,500 gpm Vertical models for capacities to 5,000 gpm In-line models for capacities to 1,500 gpm End suction models for capacities to 1,500 gpm Drives: electric motor or diesel engine Basic units and packaged systems.

กลุ่มผลิตภัณฑ์เดียวกันที่น่าซื้อ

-

Dosing device อุตสาหกรรมเคมี0.00 บาท

-

Dosing device for plastics industry0.00 บาท

-

Dosing device used in refinery0.00 บาท

-

Dosing device used in refinery0.00 บาท

-

Dosing Device0.00 บาท

-

Dosing device for chemical industry0.00 บาท

-

Dosing device used in petrochemicals0.00 บาท

-

Dosing device for other industries0.00 บาท

-

Dosing device for energy utilities0.00 บาท

-

Dosing device for energy utilities0.00 บาท

-

Dosing Device อุปกรณ์จ่ายยา0.00 บาท

-

Dosing device used in petrochemicals0.00 บาท

Facebook Comments (

454

ข้อมูล

ข้อมูล