ลงชื่อเข้าใช้

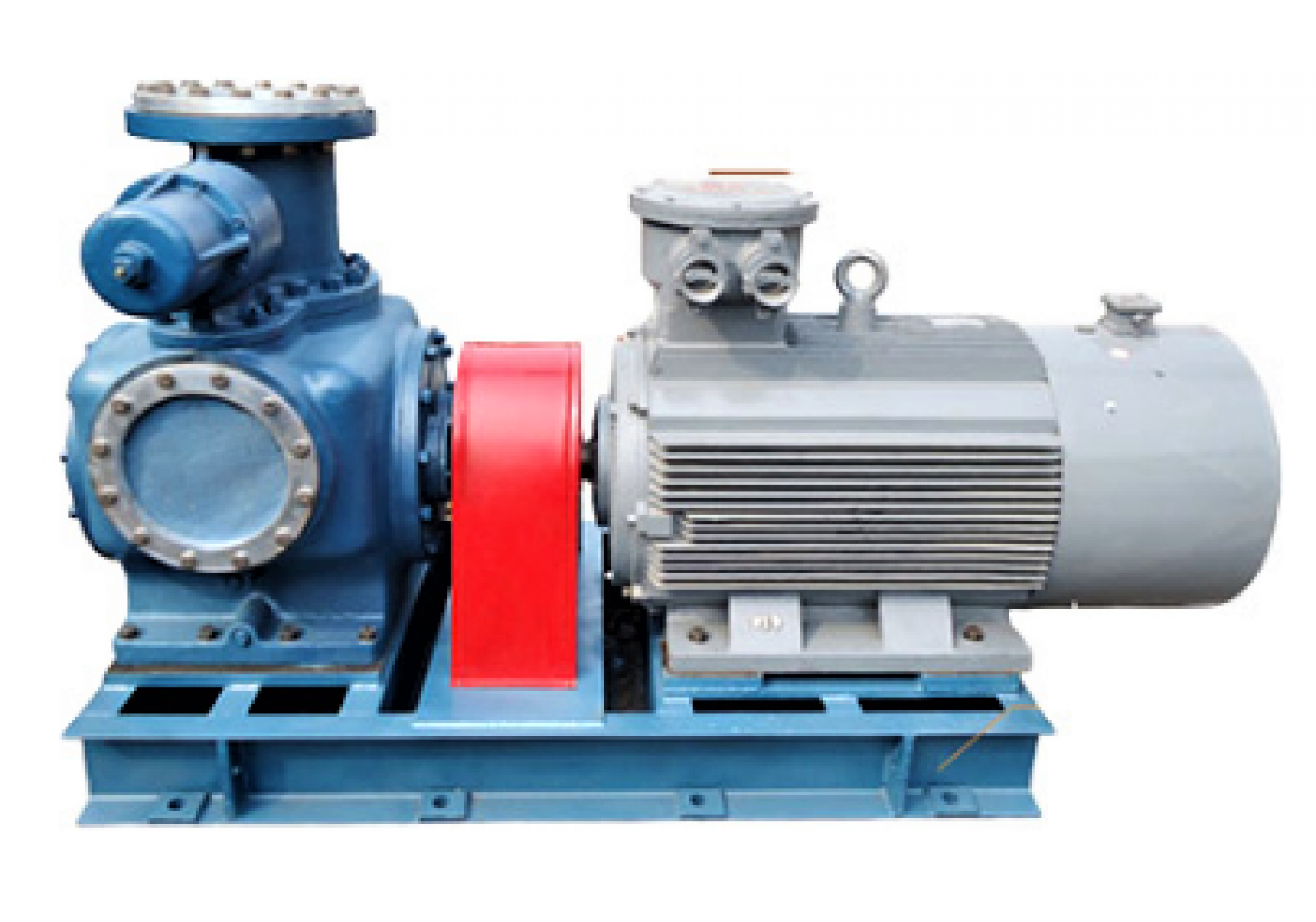

2W/W Twin Screw Pump

Specifications

Flow Rate : 1-2000 m3/h

Head Lift : <4.0 Mpa

Temperature range : -15°C-280°C

Product Description

- Through the mutual engagement of the main and driven screws in the pump body, and the cooperation of the screw and the hole of the pump

body, the twin screw pump forms a sealed cavity in the pump body. When the screw rotates, these sealed cavities continuously move forward.

Push the liquid in the sealed cavity to the outlet to discharge, so as to achieve the purpose of pumping liquid.

Generally used in

1. Oil and gas

- The twin screw pump is an ideal pump for conveying crude oil, natural gas, water and solid mixtures.

- They can be used on land and at sea. The pump can run dry, and the conveyed medium can contain gas. The compact design and special thread

profile can ensure long-distance pipeline transportation.

- Application : Multiphase crude oil transportation, thermal power plants, crude oil storage.

2. Ocean

- The twin-screw pump can be used on tankers for loading and conveying, and for lubricating the main engine.

- Application : Transport tar, asphalt, light and heavy fuel oil, crude oil, and chemicals.

3. Petrochemical and oil refineries

- The pump can transport low-viscosity liquids, including neutral, alkaline, acidic or gaseous or abrasive media.

Application : Heavy oil, asphalt, tar, heavy fuel, naphtha and chemical products.

4.Chemical industry

- Regardless of low viscosity or high viscosity, it can transport all kinds of liquids with corrosive and solid particles.

- Applications : Polymers, coatings, slurries, slurries, liquid sulfur and chemicals.

Advantage

1. The twin-screw pump conveys liquid smoothly, without pulsation, without stirring, low vibration and low noise.

2. The twin-screw pump has strong self-priming performance. When multi-phase mixed transportation, the gas content is not higher than 80%, and

the sand content is not higher than 500g/m3.

3. The external bearing structure of the twin-screw pump adopts independent lubrication and can transport various non-lubricating media.

4. The twin-screw pump is driven by synchronous gears, and there is no contact between the two rotors, even if it is idling for a short time.

5. The pump body of the twin-screw pump is equipped with a heating jacket, which can transport all kinds of clean or low-viscosity or high-viscosity

media containing small solid particles (generally, the particle diameter is less than 0.12-0.2mm)

6. The correct selection of materials for twin-screw pumps can even transport many corrosive media.

7. The twin-screw pump has a double-suction structure, and there is no axial force on the rotor.

8. The shaft end of the twin-screw pump adopts mechanical seal or bellows mechanical seal, which has the characteristics of long life, less leakage

and wide application range.

|

|

ความคิดเห็นเกี่ยวกับตัวสินค้า

ชื่อ:

เขียนความคิดเห็นของคุณ:

รูปภาพ (Upload Multiple images) :

| Review Images | Delete |

วีดีโอ (Enter Youtube video link) :

ให้คะแนน: น้อย

การชำระเงิน |

กรุณาโอนเงินเข้าบัญชี ธนาคาร กสิกรไทย สาขา คลอง 6 ธัญบุรี ชื่อบัญชี บจก.เจช้อปดีแอล เลขที่บัญชี 119-347-595-3 โปรติดต่อฝ่ายขาย 061-5597151 ก่อนการโอน |

|

|

หมายเลขอ้างอิง: BNMBNMUY

Capacity: 200 GPM – 2000 GPM

Pressures: 40 – 355 psi

Maximum Working Pressures: 290 to 395 PSI

Speed: 1480,1760, 2900,2980, 3000 RPM

Dynamically Balanced Impeller extends bearing life and ensures smoother operation.

Designed and built as per UL 448 AND NFPA20 for maximum reliability.

Constructed in variety of metallurgies.

Available in 50 Hz and 60 Hz.

Drivers with gear boxes at electric and diesel speeds.

Designed for easy maintenance without interfering with piping.

Open line shaft, water lubricated construction for ease of maintenance.

Self-Venting Design eliminates vapor lock and the need for automatic air release valve

ประตูน้ำเหล็กหล่อ : ลิ้นยกแบบรองลิ้นโลหะ สำหรับงานประปา CASR IRON GATE VALVE – METAL SEATED FOR WATER SERVICES MODEL (DN-CI-MS) TIS 256 PN 6, 10, 16 TIS 432 PN 6, 10, 16 DIN 3352 PN 10, 16 BS 5150 PN 6, 10, 16 BS EN 1171 PN 6, 10, 16 Size DN80-1200 mm. ประตูน้ำ (Gate Valve) เหล็กหล่อใต้ดิน ชนิดลิ้นยกแบบรองลิ้นโลหะ มอก.256 ประตูน้ำ (Gate Valve) เหล็กหล่อใต้ดิน ชนิดลิ้นยกแบบรองลิ้นโลหะ สำหรับงานประปา มอก.256 วาล์วได้ผลิตและทดสอบตามมาตรฐาน BS 5150 PN10/16/25, BS EN 1171:2002, BS EN 1074-2, TIS 432 PN 6 / 10 / 16 และสอดคล้องกับข้อกำหนดของ MSS-SP-70 class 125 / 250 ใช้งานได้กับทั้งน้ำ, อากาศและไอน้ำ ตุณลักษณะ - ตัวเรือนเป็นเหล็กหล่อ - ปลายประตูน้ำ สามารถเป็นหน้าจาน, เกลียวและปลายเรียบ - หน้าจานสามารถเจาะให้เข้ากับ ANSI B16.1, ANSI B16.5, BS4504, BS10, BS EN 1092-2, BS 4772, AS2129, DIN, JIS และอื่น ๆ - เลือกตัวขับได้หลากหลาย ตามที่ต้องการเช่น พวงมาลัย, แป้นประแจขันหรือ cap, พวงมาลัยโซ่, เฟืองตรง, เฟืองดอกจอก, นิวเมติก, ไฮดรอลิก และไฟฟ้า

Fire Pump Controller UL FM standard for Jockey Pump Type You have decided to reduce the risk of fire damage to your facility by installing a UL, ULC listed fire pump system. Your next decision is which system to purchase. You want a fire pump that is proven in installations worldwide. Manufactured by an professional with vast experience in the fire protection field. You want complete service to field start-up. You want a Engine Controller Fire Protection UL FM Providing Pumping Solutions TONGKE Can Fulfill Your Requirements: Complete in-house fabrication capabilities Mechanical-run test capabilities with customer furnished equipment for all NFPA standards Horizontal models for capacities to 2,500 gpm Vertical models for capacities to 5,000 gpm In-line models for capacities to 1,500 gpm End suction models for capacities to 1,500 gpm Drives: electric motor or diesel engine Basic units and packaged systems.

กลุ่มผลิตภัณฑ์เดียวกันที่น่าซื้อ

Facebook Comments (

46

ข้อมูล

ข้อมูล